ʻO nā mea maikaʻi o nā pōhaku lepo magnesia:kū'ē i ka erosion slag a me ke kū'ē kū'ē wela wela.I ka wā ma mua, ʻo ka hemahema o nā pōhaku lepo MgO-Cr2O3 a me nā pōhaku lepo dolomite ʻo ia ka hoʻomoʻa ʻana i nā ʻāpana slag, ka hopena i ka spalling structural, e alakaʻi ana i ka pōʻino mua.Ma ka hoʻohui ʻana i ka graphite, ua hoʻopau nā pōhaku kalapona magnesia i kēia hemahema.ʻO kona hiʻohiʻona ʻo ka slag wale nō ke komo i loko o ka ʻili hana, no laila ke ʻano o ka hopena i hoʻopaʻa ʻia i ka ʻili hana, ʻoi aku ka liʻiliʻi o ka peeling a me ke ola lawelawe lōʻihi.

I kēia manawa, ma waho aʻe o ka asphalt kuʻuna a me nā pōhaku lepo magnesia i hoʻopaʻa ʻia i ka resin (me nā pōhaku magnesia i hoʻopaʻa ʻia i ka aila).ʻo nā pōhaku lepo kalapona magnesia i kūʻai ʻia ma ka mākeke:

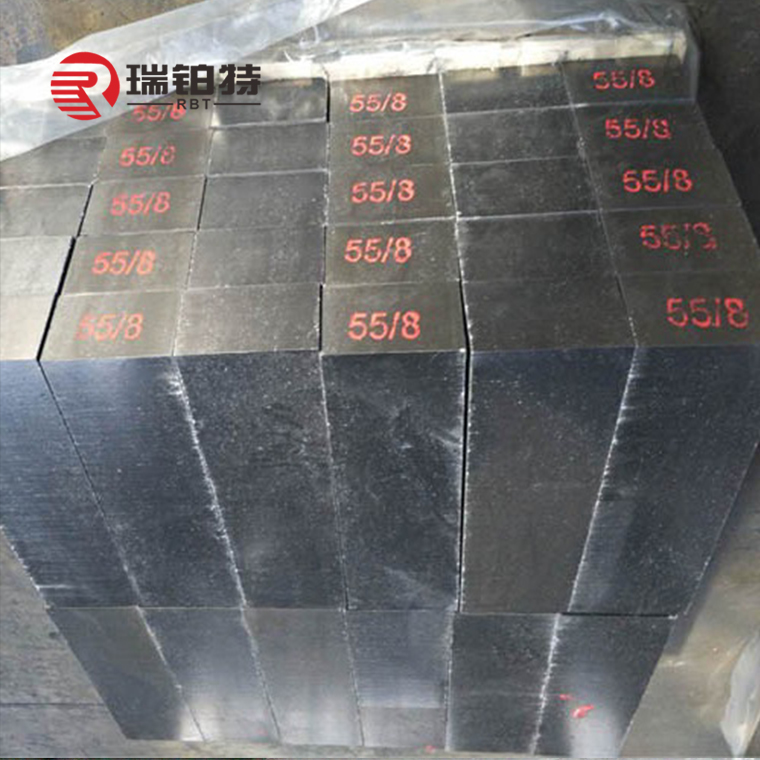

(1) ʻO nā pōhaku lepo kalapona Magnesia i hanaʻia me ka magnesia i loaʻa ka 96% ~ 97% MgO a me ka graphite 94% ~ 95% C;

(2) ʻO nā pōhaku lepo kalapona Magnesia i hana ʻia me ka magnesia i loaʻa ka 97.5% ~ 98.5% MgO a me ka graphite 96% ~ 97% C;

(3) ʻO nā pōhaku kalapona Magnesia i hana ʻia me ka magnesia i loaʻa ka 98.5%~99% MgO a me 98%~C graphite.

Wahi a ka ʻike kalapona, ua māhele ʻia nā pōhaku kalapona magnesia i:

(I) Nā pōhaku lepo magnesia i hoʻopaʻa ʻia i ka aila (ʻoi aku ka nui o ke kalapona ma lalo o 2%);

(2) ʻO nā pōhaku lepo magnesia i hoʻopaʻa ʻia (carbon content emi mai ka 7%);

(3) Synthetic resin i hoʻopaʻa ʻia i ka magnesia carbon brick (carbon content he 8% ~ 20%, a hiki i ka 25% i kekahi mau hihia).Hoʻohui pinepine ʻia nā antioxidants i ka asphalt/resin bonded magnesia carbon bricks (he 8% a hiki i ka 20%) ka waihona kalapona.

Hoʻokumu ʻia nā pōhaku kalapona Magnesia ma ka hui ʻana i ke one MgO maʻemaʻe kiʻekiʻe me ka graphite scaly, kalapona ʻeleʻele, a me nā mea ʻē aʻe. ka hui 'ana Ua ho'oki'eki'e 'ia ka mahana o ka 'ano mea hana a kokoke i ka 100 ~ 200 ℃, a hui pū 'ia me ka mea ho'opa'a no ka loa'a 'ana o ka lepo i kapa 'ia he MgO-C (ka hui 'ōma'oma'o).ʻO ka mea lepo MgO-C e hoʻohana ana i ka resin synthetic (ka nui o ka resin phenolic) i hoʻoheheʻe ʻia i kahi kūlana anu;ʻo ka MgO-C lepo lepo i hui pū ʻia me ka asphalt (hoʻomaʻamaʻa ʻia i kahi ʻano wai) ua hoʻoheheʻe ʻia i loko o kahi kūlana wela (ma kahi o 100 ° C).E like me ka nui o ka pūʻulu a me nā koi hana o nā huahana MgO-C, nā mea hoʻoheheʻe vacuum, nā mea hana hoʻoheheʻe ʻia, nā extruders, nā isostatic presses, nā paʻi wela, nā mea hoʻomehana, a me nā lako ramming hiki ke hoʻohana ʻia e hana i nā mea lepo MgO-C.i ke ʻano kūpono.Hoʻokomo ʻia ke kino MgO-C i hoʻokumu ʻia i loko o kahi kiln ma 700 ~ 1200 ° C no ka mālama ʻana i ka wela e hoʻohuli i ka mea hoʻopaʻa paʻa i carbon (ua kapa ʻia kēia kaʻina hana carbonization).I mea e hoʻonui ai i ka paʻa o nā pōhaku kalapona magnesia a hoʻoikaika i ka hoʻopaʻa ʻana, hiki ke hoʻohana ʻia nā mea hoʻopihapiha e like me nā mea paʻa e hoʻopili i nā pōhaku.

I kēia mau lā, hoʻohana nui ʻia ka resin synthetic (ʻoi aku ka resin phenolic) e like me ka mea hoʻopaʻa paʻa o nā pōhaku kalapona magnesia.ʻO ka hoʻohana ʻana i ka resin synthetic i hoʻopaʻa ʻia i nā pōhaku kalapona magnesia i loaʻa i kēia mau pono kumu:

(1) Hiki i nā hiʻohiʻona kaiapuni ke hana a hana i kēia mau huahana;

(2) ʻO ke kaʻina hana o ka hana ʻana i nā huahana ma lalo o nā kūlana huikau anuanu e mālama i ka ikehu;

(3) Hiki ke hana ʻia ka huahana ma lalo o nā kūlana hoʻōla ʻole;

(4) Ke hoʻohālikelike ʻia me ka tar asphalt binder, ʻaʻohe wahi palaki;

(5) Hiki i ka hoʻonui ʻia ʻana o ke kalapona (ʻoi aku ka graphite a i ʻole ka lanahu bituminous) hiki ke hoʻomaikaʻi i ke kūpaʻa ʻaʻahu a me ka pale ʻana.

Ka manawa hoʻouna: Feb-23-2024