Mea Hoʻomaloʻo Silicon Carbide Lgniter

Nā Māhele Huahana

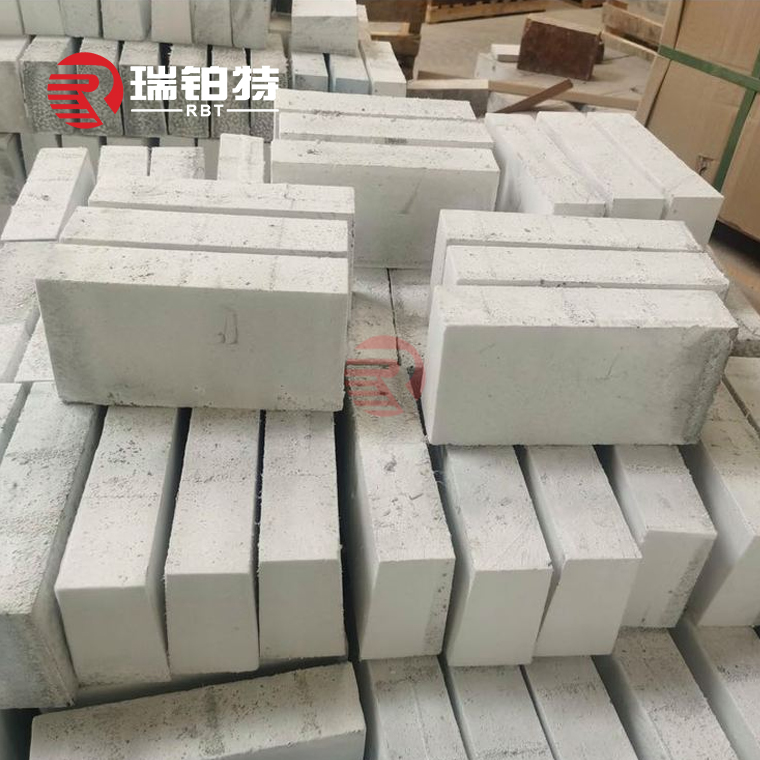

1. Nā huahana carbide silicon sintered i hana ʻia (Nā Huahana RBSiC)

ʻO ka silicon carbide i hoʻopaʻa ʻia (RBSiC) kahi mea keramika ʻenekinia holomua e hoʻopuka i kahi pae hoʻopaʻa silicon carbide ma ka hoʻopili ʻana i ke kalapona manuahi me ka silicon wai ma lalo o nā kūlana wela kiʻekiʻe. ʻO kāna mau ʻāpana kumu e komo pū me ka matrix silicon carbide (SiC) a me ka silicon manuahi (Si). Hāʻawi ka mea mua i nā waiwai mechanical maikaʻi loa, ke kūpaʻa ʻana i ka ʻaʻahu a me ke kūpaʻa wela kiʻekiʻe.

ʻoiai ʻo ka mea hope e hoʻopiha i nā pores ma waena o nā ʻāpana silicon carbide e hoʻonui i ka mānoanoa a me ke kūpaʻa o ka mea.

(1) Nā ʻano:

Paʻa o ka mahana kiʻekiʻe:Ka mahana hana kiʻekiʻe loa he 1350℃.

Ke kūpaʻa ʻana i ke kapa komo a me ke kūpaʻa i ka pala:Kūpono no nā kūlana hana koʻikoʻi o ke kiʻekiʻe o ka mahana, ka waikawa, ka alkali a me ka metala i hoʻoheheʻe ʻia.

ʻO ke alakaʻi wela kiʻekiʻe a me ke koina hoʻonui wela haʻahaʻa:ʻO ke kiʻekiʻe o ka conductivity thermal e like me 120-200 W/(m·K), a ʻo ke coefficient hoʻonui thermal he 4.5 × 10⁻⁶ K⁻¹ wale nō, kahi e pale pono ai i ka haki ʻana o ka thermal a me ka luhi thermal.

Pale ʻokikene:Hoʻokumu ʻia kahi papa pale silica mānoanoa ma luna o ka ʻili ma ke ana wela kiʻekiʻe e hoʻolōʻihi i ke ola lawelawe.

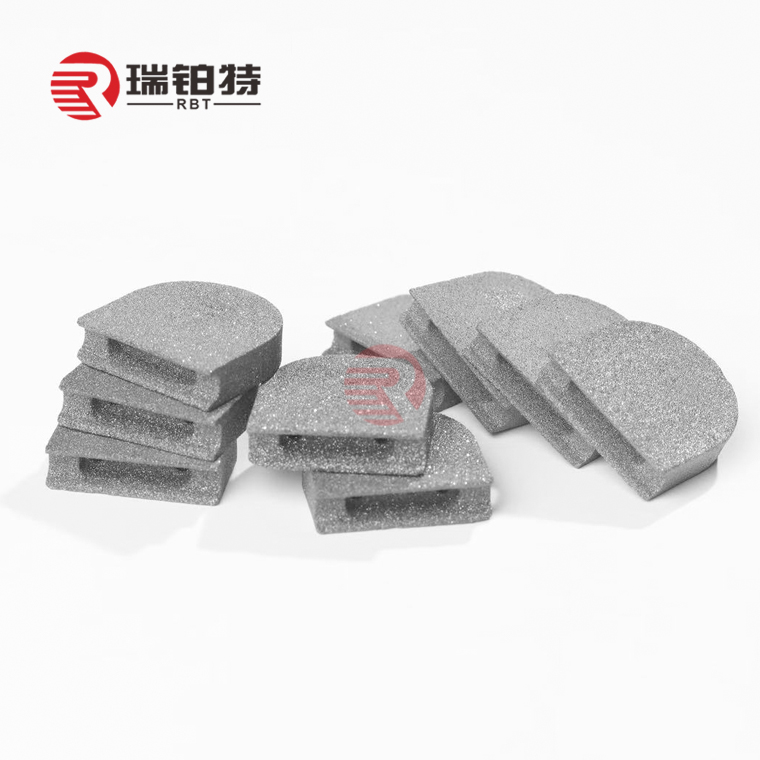

(2) Nā Huahana Nui:

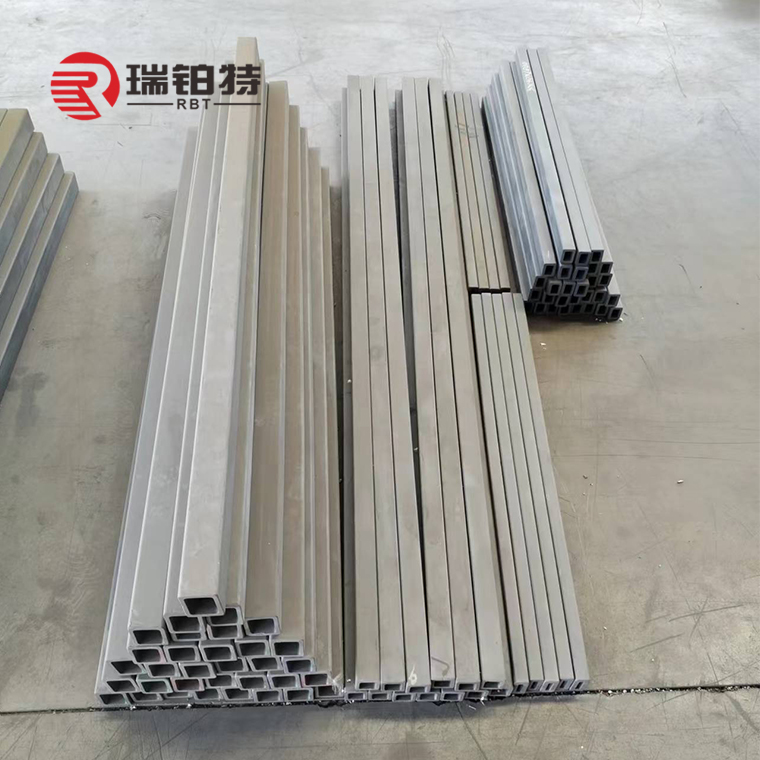

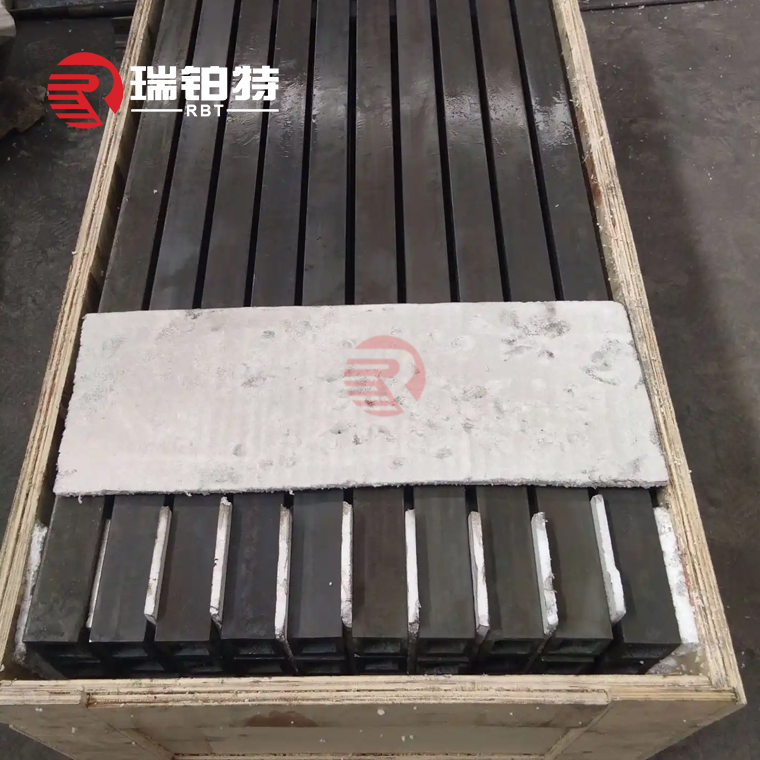

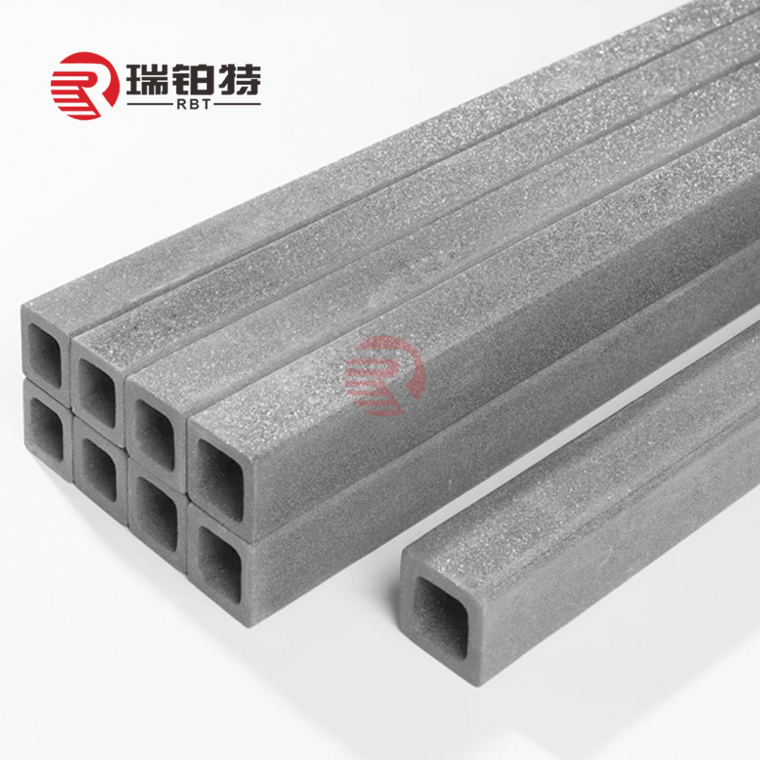

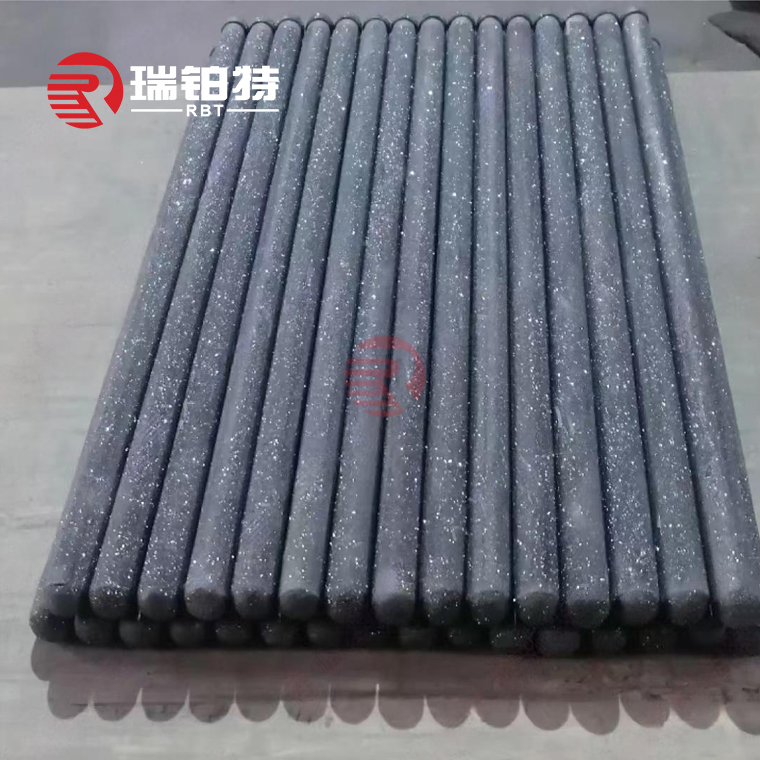

?Kaula kalapona silikona:hoʻohana ʻia no ka hoʻolālā halihali o nā umu tunnel, nā umu shuttle a me nā umu ʻoihana ʻē aʻe, me ke kūpaʻa wela kiʻekiʻe maikaʻi loa.

?

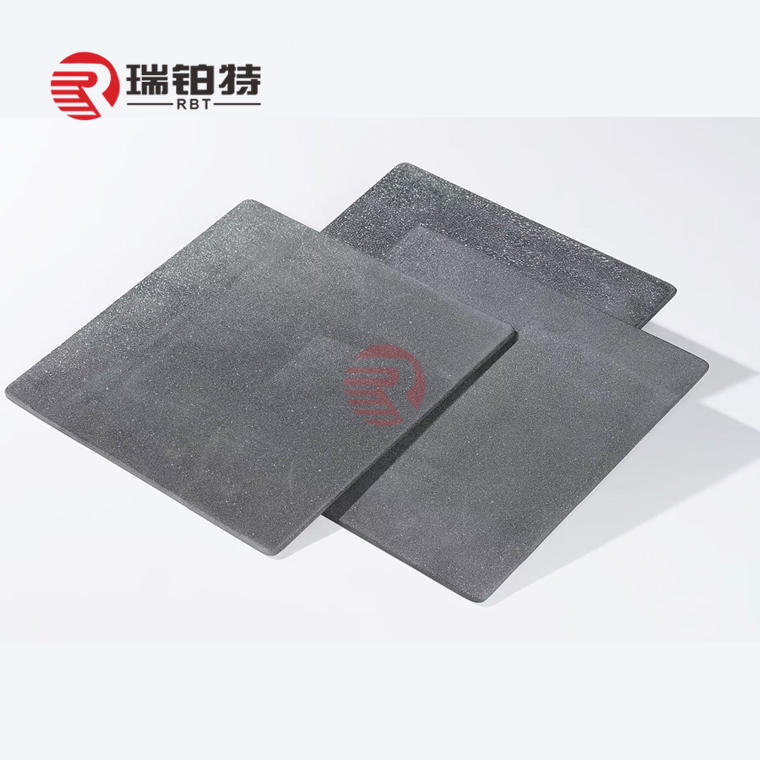

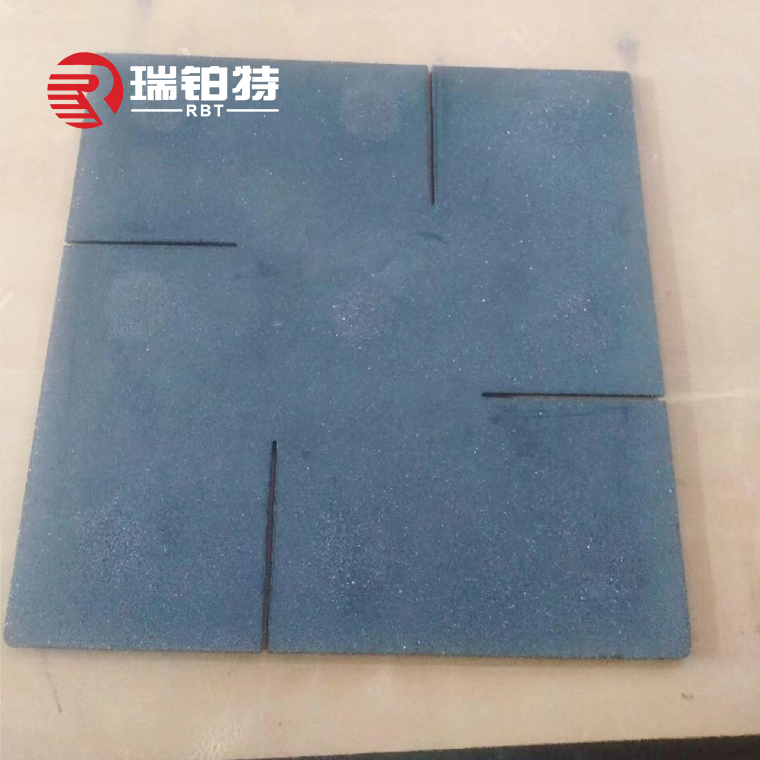

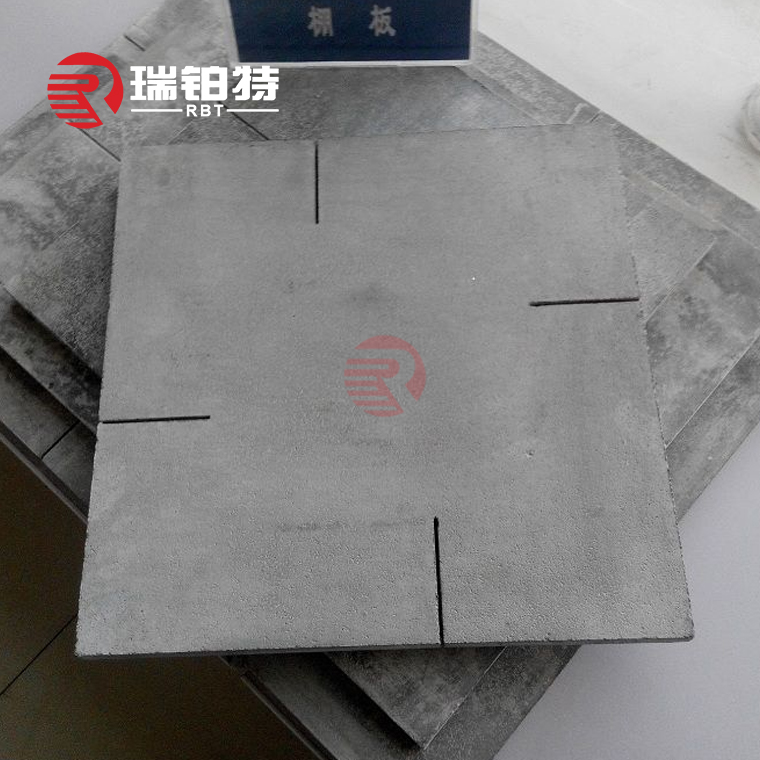

Papa kalapona silikona:hoʻohana ʻia no nā mea refractory i loko o nā umu, me nā ʻano o ka hoʻopaʻa ʻana o ka oxide.

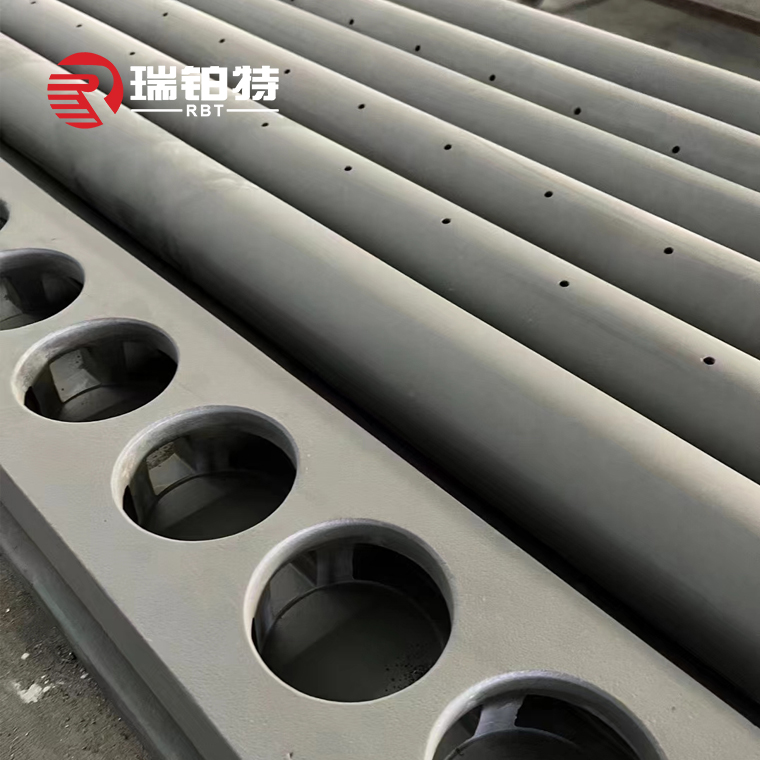

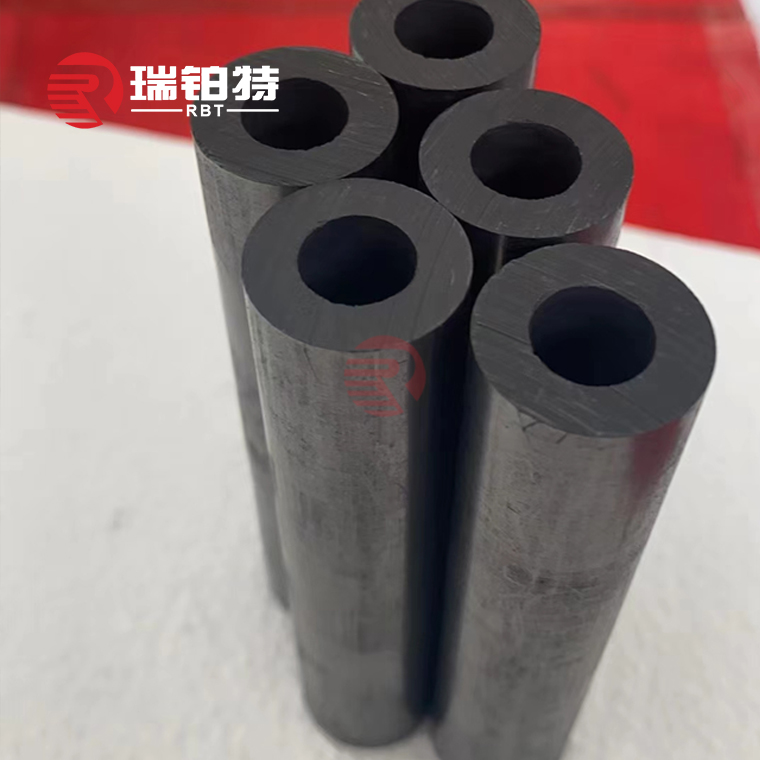

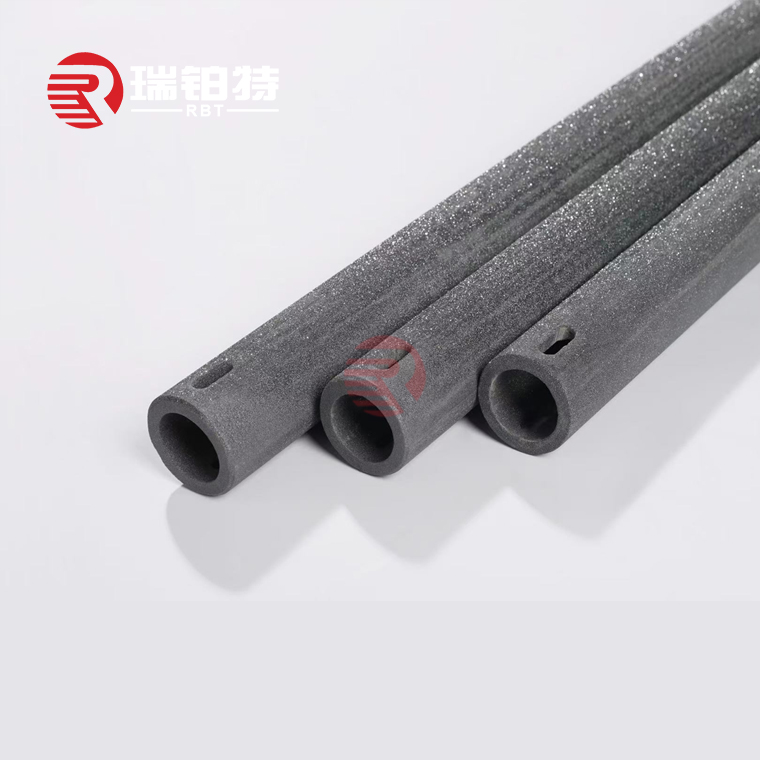

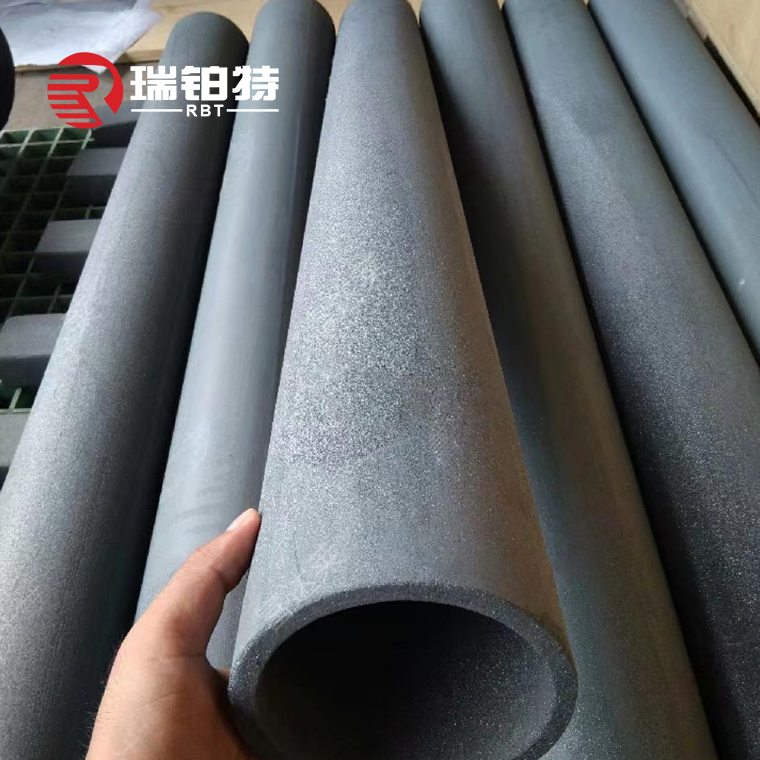

Paipu kalapona silikona:hoʻohana ʻia no nā paipu a me nā ipu i nā ʻano wela kiʻekiʻe like ʻole.

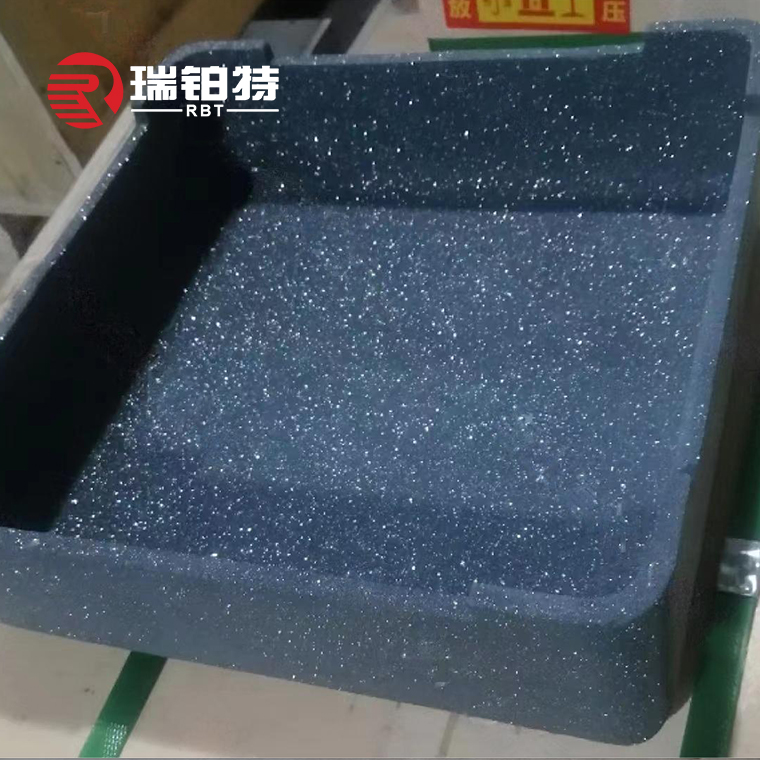

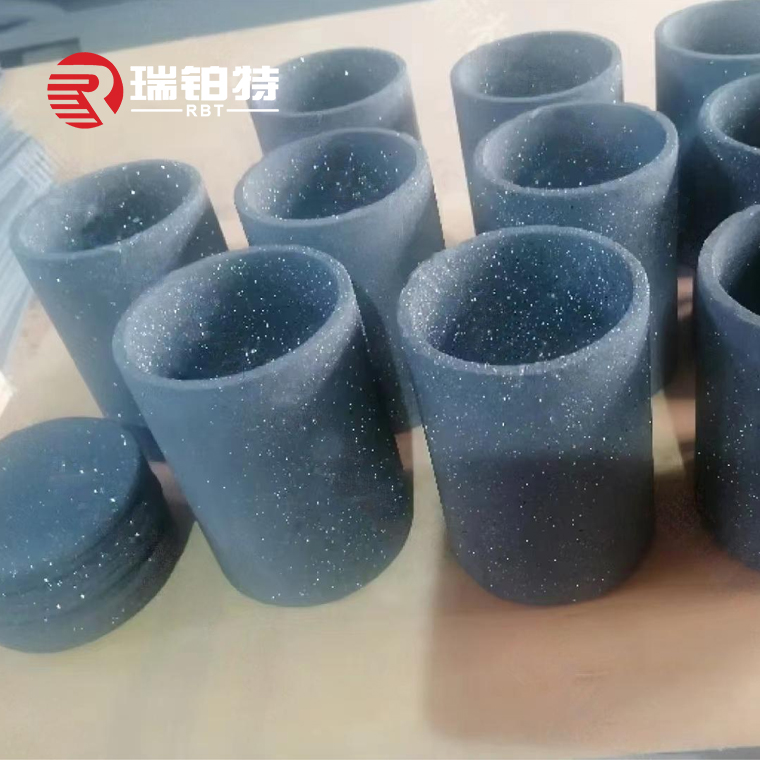

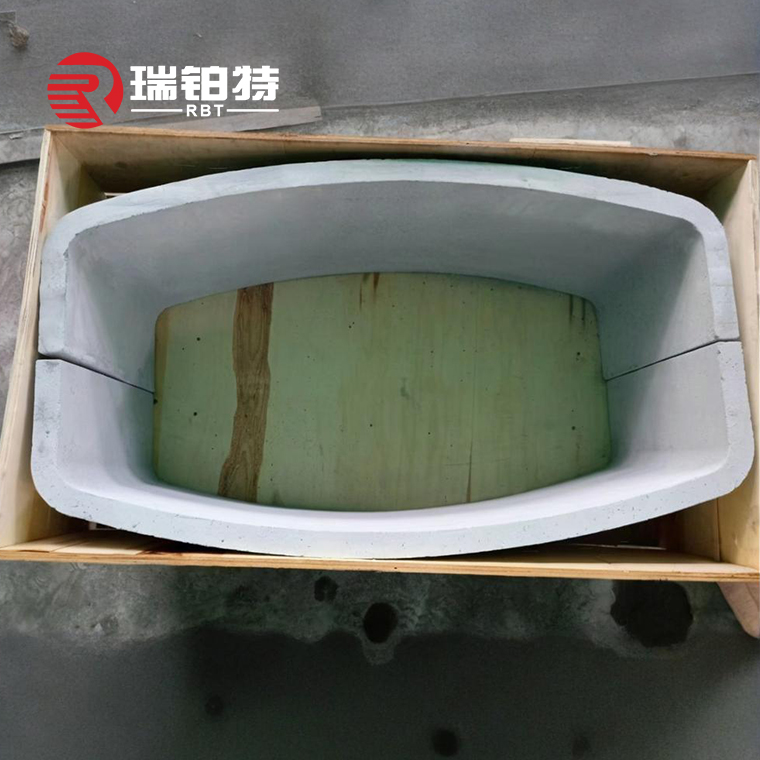

ʻO ke ipu hoʻoheheʻe silikona carbide a me ka sagger:hoʻohana ʻia no ka hoʻoheheʻe ʻana i ka mahana kiʻekiʻe a me ka mālama ʻana i nā mea.

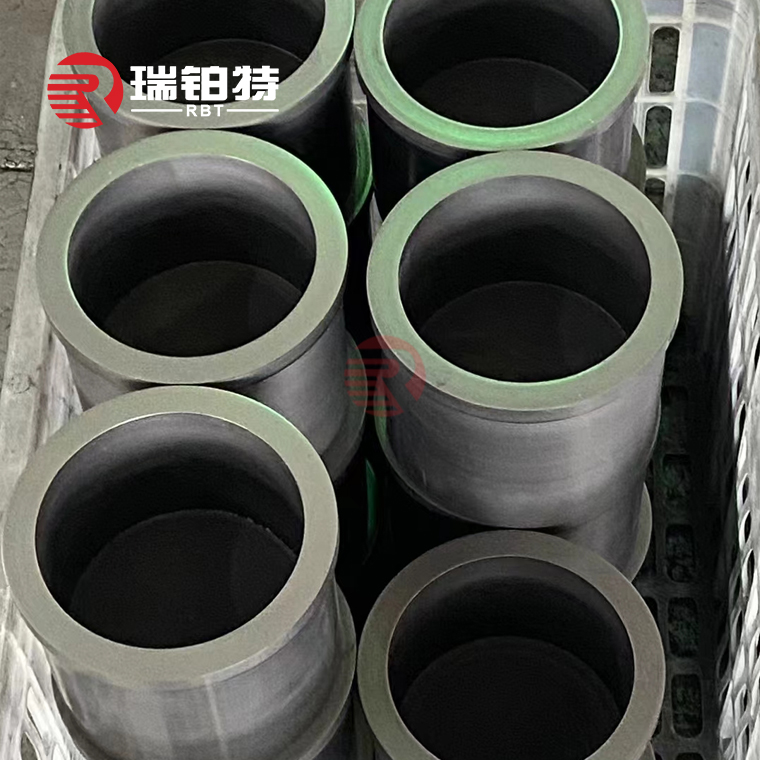

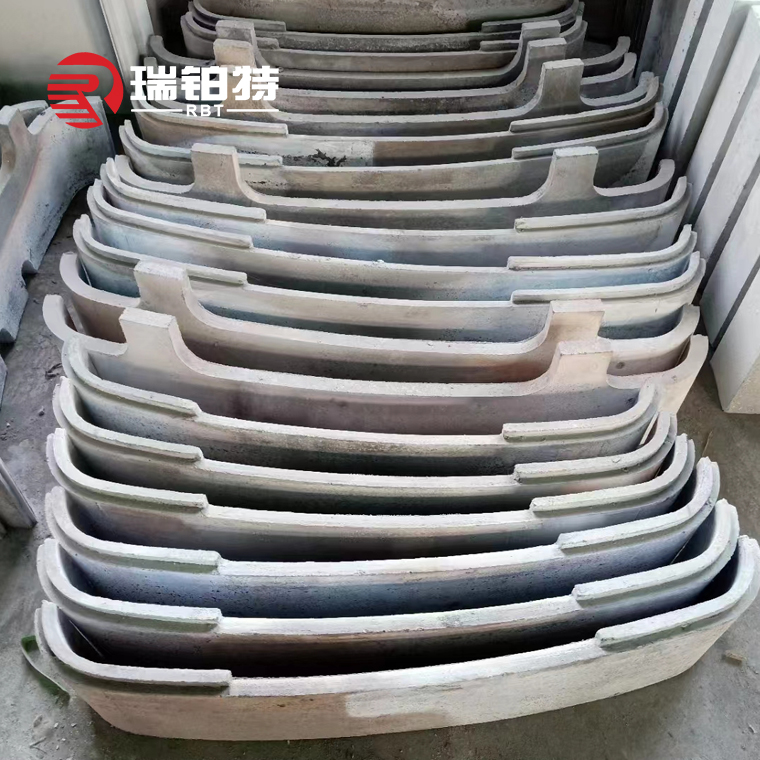

Apo sila silikona carbide:hoʻohana nui ʻia ma nā kahua o nā kaʻa, aerospace a me ka ʻoihana kemika, a hiki ke mālama i ka hana sila hilinaʻi i nā wahi mahana kiʻekiʻe a me ke kaomi kiʻekiʻe.

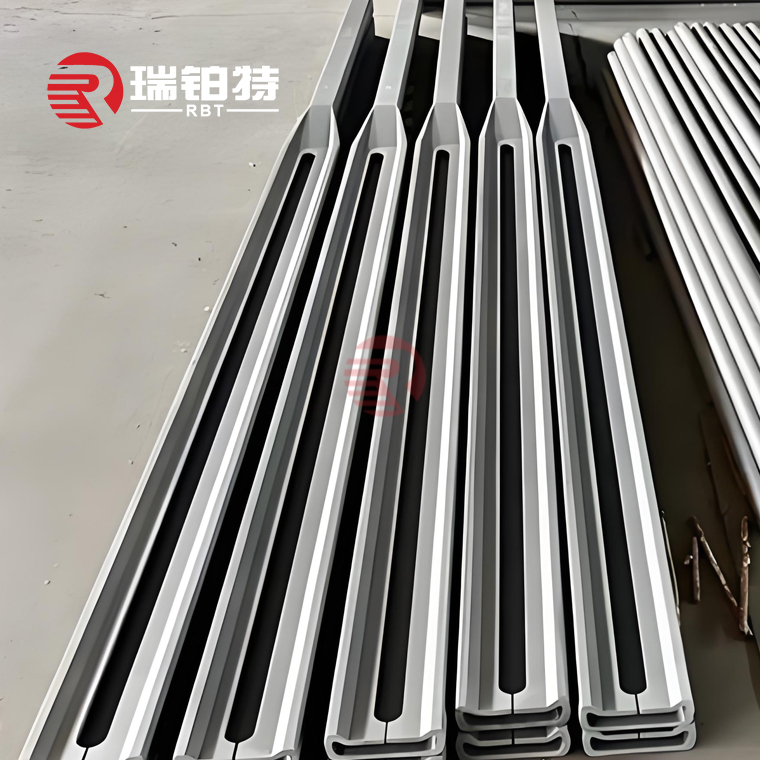

ʻO ka wili kalapona silikona:hoʻohana ʻia no nā umu wili, me nā ʻano o ka anti-oxidation, ka ikaika flexural wela kiʻekiʻe a me ke ola lawelawe lōʻihi.

Nā paipu hoʻoluʻu Silicon carbide:hoʻohana ʻia no ka ʻāpana hoʻoluʻu o nā umu wili, me ke kūpaʻa maikaʻi i ka koʻikoʻi

anu a me ka wela.

Silicon carbide bunner nozzle:hoʻohana ʻia no nā ʻaila like ʻole, kinoea a me nā umu ʻoihana ʻē aʻe, me nā ʻano o ke kūpaʻa anu loa a me ka wela, ke kūpaʻa ʻana i ka ʻaʻahu, ke kūpaʻa wela kiʻekiʻe, a pēlā aku.

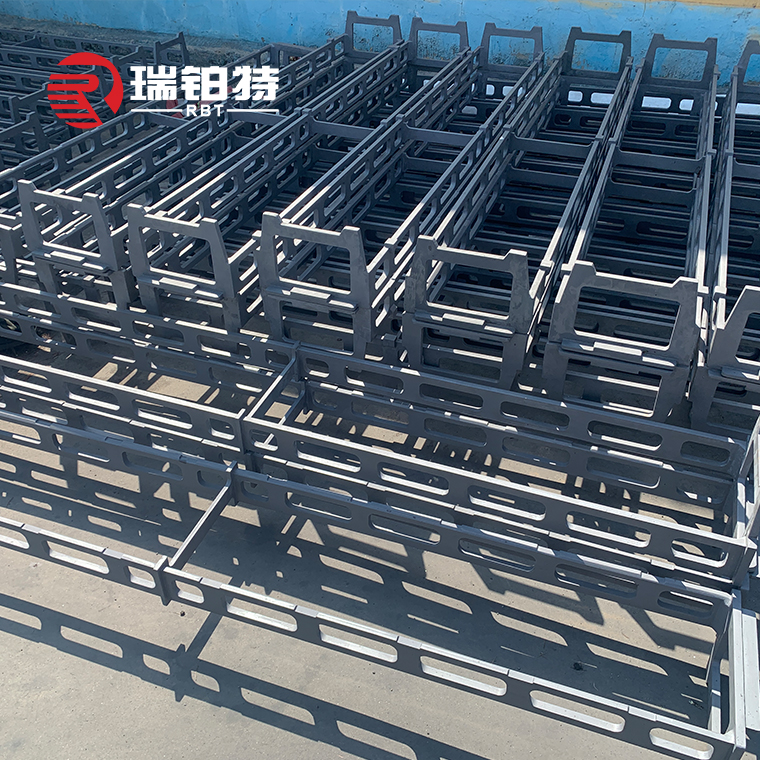

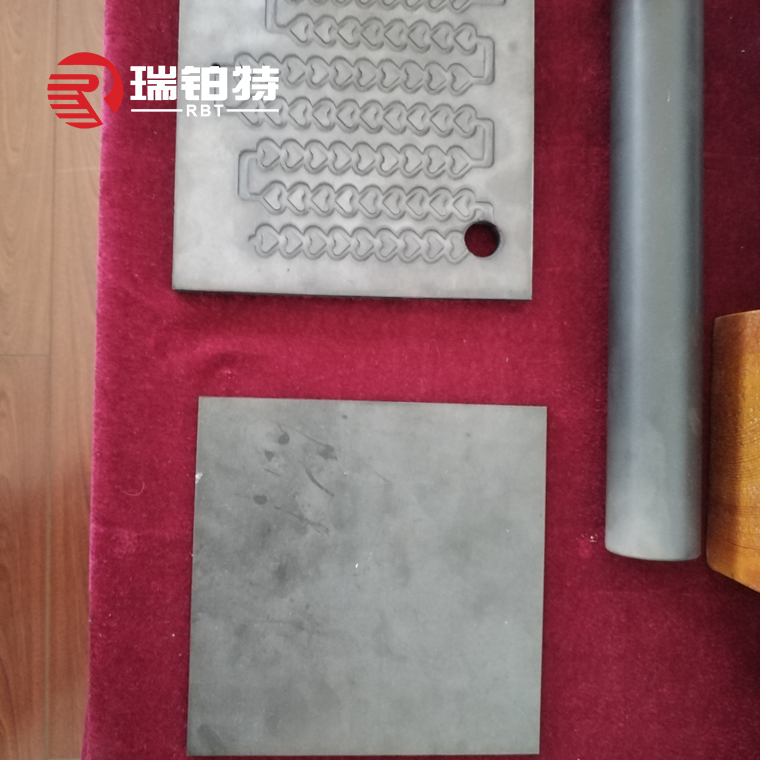

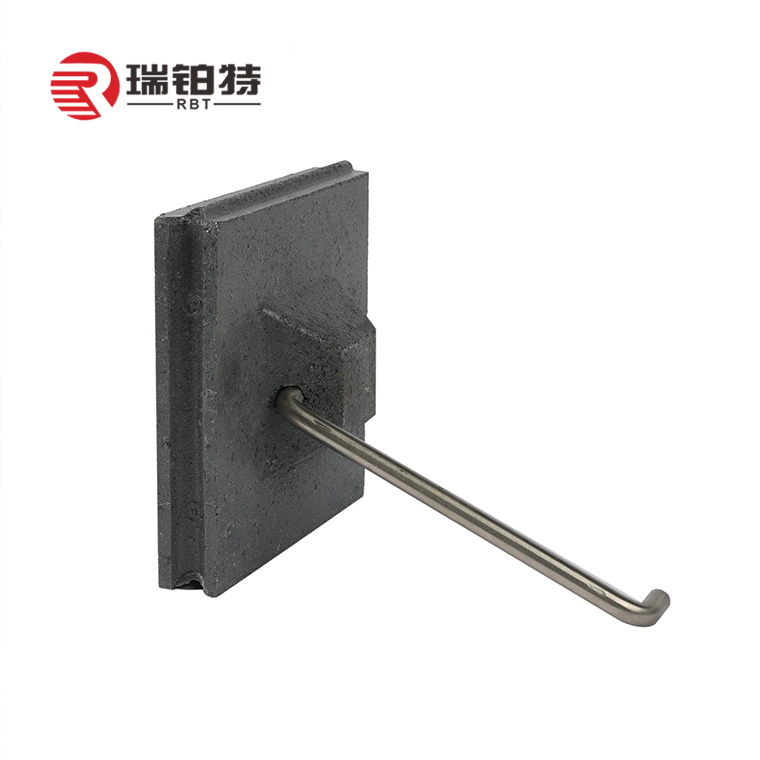

Nā ʻāpana ʻano kūikawā i hoʻopilikino ʻia:Hana ʻia maʻamau o nā ʻāpana ʻano kūikawā like ʻole e like me nā pono o ka mea kūʻai aku, e like me nā papa ʻano iʻa, nā koʻokoʻo kau, nā ʻāpana kākoʻo, a pēlā aku.

Nā Kiʻi kikoʻī

Kukui Silicon Carbide

Hoe Cantilever Silicon Carbide

ʻŌmole Silicon Carbide

Paipu puhi ʻo Silicon Carbide

Nā Paipu Hoʻoluʻu Silicon Carbide

ʻŌmole Silicon Carbide

Pale Waʻa Silicon Carbide

ʻO ka uhi pale ʻaʻahu

Waʻa Wafer Silicon Carbide

Papa Kuhikuhi Huahana

| Nā Huahana RBSiC (SiSiC) | ||

| Mea | ʻĀpana | ʻIkepili |

| Mahana Kiʻekiʻe o ka Noi ʻana | ℃ | ≤1350 |

| Ka nui o ka paʻa | g/cm3 | ≥3.02 |

| Ka Porosity Hāmama | % | ≤0.1 |

| Ikaika Kūlou | Mpa | 250 (20 ℃); 280 (1200 ℃) |

| Modulus o ka Elasticity | GPA | 330 (20 ℃); 300 (1200 ℃) |

| Ka Hoʻokele Wela | W/mk | 45 (1200 ℃) |

| Ka helu hoʻonui wela | K-1*10-6 | 4.5 |

| Ka Paʻakikī o Moh | | 9.15 |

| Palekana ʻAkika Alkaline | | Maikaʻi loa |

2. Nā huahana silicon carbide sintered pressureless(Nā Huahana SSiC)

ʻO nā huahana silicon carbide sintered pressureless he ʻano mea keramika ʻenehana kiʻekiʻe i hoʻomākaukau ʻia e ke kaʻina hana sintering pressureless. ʻO kāna ʻāpana nui ka silicon carbide (SiC), a ua hoʻohui ʻia kekahi hapa o nā mea hoʻohui. Ma o ka ʻenehana keramika holomua, ua hana ʻia i mau keramika kiʻekiʻe non-porous, seamless, a me ka stress-free.

(1) Nā ʻano:

Ke kūpaʻa wela kiʻekiʻe:hoʻohana maʻamau ma 1800℃;

Ka hoʻokele wela kiʻekiʻe:like me ke alakaʻi wela o ka graphitenā mea hana;

Paʻakikī kiʻekiʻe:ʻo ka paʻakikī ka lua wale nō i ka daimana a me ka cubic boron nitride;

Ke kū'ē'ē i ka palaho:ʻAʻohe pala o ka waikawa ikaika a me ka alkali ikaika, a ʻoi aku ka maikaʻi o kona kūpaʻa i ka pala ma mua o ka tungsten carbide a me ka alumini oxide;

Māmā ke kaumaha:ka nui o ka nui 3.10g/cm3, kokoke i ka alumini;

ʻAʻohe deformation:ka palena hoʻonui wela haʻahaʻa loa,

Kūpaʻa i ka haʻalulu wela:hiki i ka mea ke kū i nā loli wela wikiwiki, ka haʻalulu wela, ka hoʻomaha wikiwiki a me ka hoʻomehana ʻana, a he hana paʻa.

(2) Nā Huahana Nui:

Nā apo sila:Hoʻohana pinepine ʻia nā huahana silicon carbide sintered pressureless e hana i nā apo sila a me nā bearings paheʻe e kūʻē i ka ʻaʻahu a me ka palaho.

Nā ʻāpana mīkini:Me nā bearings wela kiʻekiʻe, nā sila mechanical, nā nozzles, nā valves pneumatic, nā kino pamu, nā mea paʻa, a pēlā aku.

Nā lako hana kemika:Hoʻohana ʻia e hana i nā paipu pale i ka pala, nā pahu mālama, nā mea hana a me nā sila.

Nā mea uila:I ka ʻoihana mana, hoʻohana ʻia ka silicon carbide sintered pressureless e hana i nā resistors wela kiʻekiʻe, nā mea hoʻomehana uila a me nā kuapo voltage kiʻekiʻe.

Nā lako hale umu:E like me nā kiʻikuhi kūkulu ukana, nā wili, nā nozzles lapalapa, nā paipu hoʻoluʻu, a me nā mea ʻē aʻe i loko o nā umu tunnel, nā umu shuttle a me nā umu ʻoihana ʻē aʻe.

Nā Kiʻi kikoʻī

Apo Sila Silicon Carbide

Paipu Silicon Carbide

Nā Liner Silicon Carbide

Kukui Silicon Carbide

Papa Silicon Carbide

Paila Wili Silicon Carbide

Papa Kuhikuhi Huahana

| Nā Huahana SSiC | ||

| Mea | ʻĀpana | Hopena |

| Paʻakikī | HS | ≥115 |

| Ka helu porosity | % | <0.2 |

| Ka nui o ka paʻa | g/cm3 | ≥3.10 |

| Ikaika Hoʻopaʻa | Mpa | ≥2500 |

| Ikaika Kūlou | Mpa | ≥380 |

| Ka helu o ka hoʻonui ʻana | 10-6/℃ | 4.2 |

| ʻIke o SiC | % | ≥98 |

| Si manuahi | % | <1 |

| Modulus Elastic | GPA | ≥410 |

| Mahana Kiʻekiʻe o ka Noi ʻana | ℃ | 1400 |

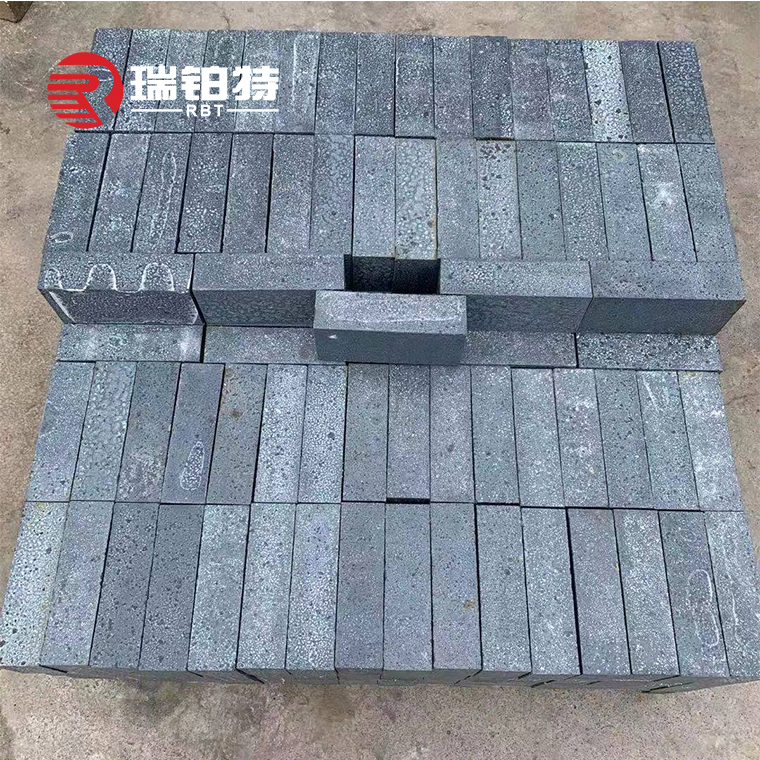

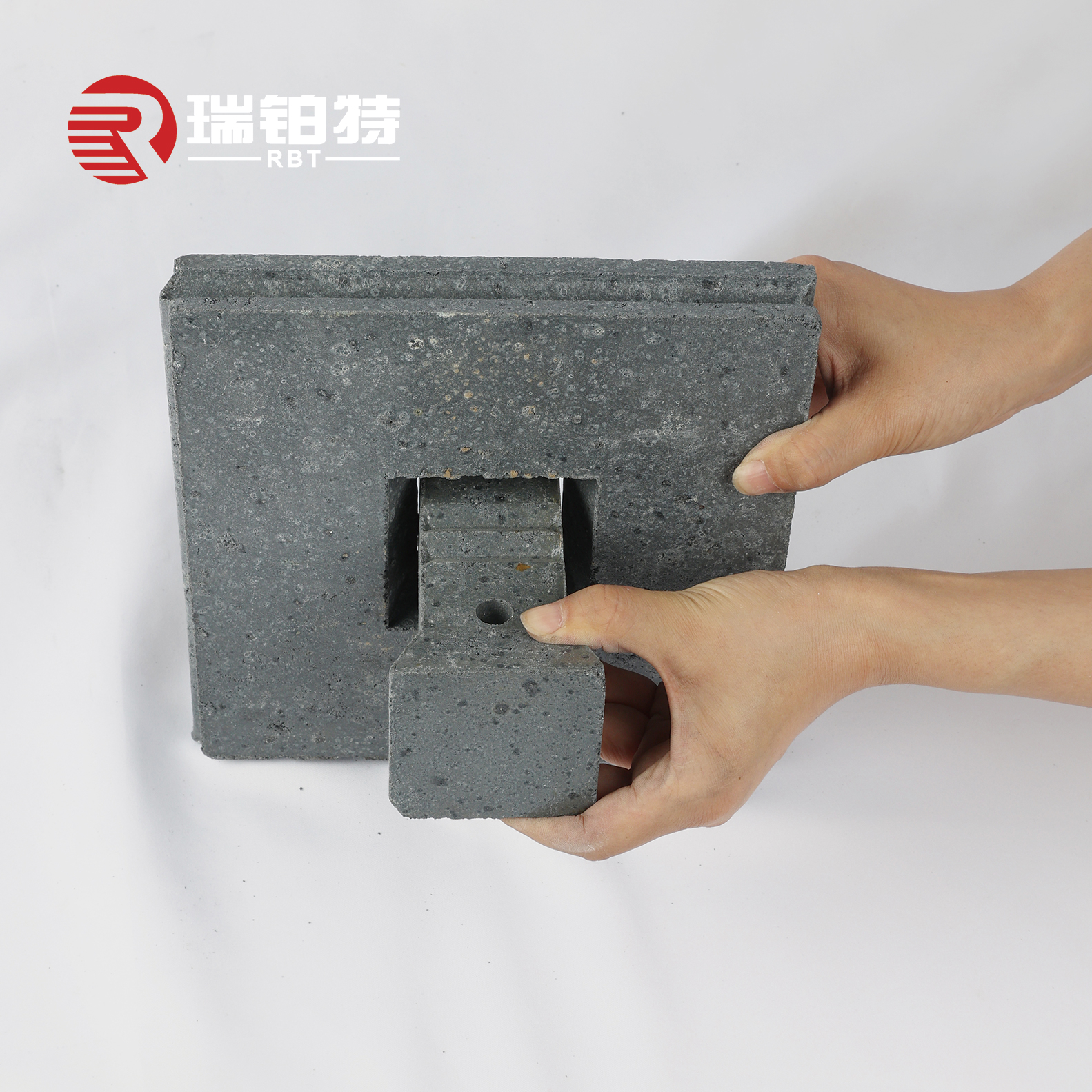

3. Huahana carbide silicon i hoʻopili hou ʻia (Nā Huahana RSiC)

ʻO nā huahana Silicon Carbide i hoʻopili hou ʻia he huahana refractory i hana ʻia me ka silicon carbide maʻemaʻe kiʻekiʻe ma ke ʻano he mea maka. ʻO kona hiʻohiʻona nui ʻaʻohe pae lua a ua haku ʻia me 100% α-SiC.

(1) Nā ʻano:

Paʻakikī kiʻekiʻe:ʻO kona paʻakikī ka lua o ka daimana wale nō, a he ikaika mechanical kiʻekiʻe loa a me ka paʻakikī.

Ke kūpaʻa wela kiʻekiʻe:Hiki iā ia ke mālama i ka hana paʻa i ke kaiapuni wela kiʻekiʻe a kūpono hoʻi no ka pae mahana o 1350 ~ 1600 ℃.

Ke kūpaʻa ikaika i ka pala:Loaʻa iā ia ke kūpaʻa kiʻekiʻe i ka pala i nā ʻano pāpaho like ʻole a hiki ke mālamanā waiwai mechanical no ka manawa lōʻihi i nā ʻano kaiapuni corrosive like ʻole.

Ke kūpaʻa maikaʻi ʻana i ka oxidation:He kūpaʻa maikaʻi kona i ka oxidation a hiki ke hana paʻa i nā mahana kiʻekiʻe.

Ke kūpaʻa haʻalulu wela maikaʻi:Hana maikaʻi ia i kahi kaiapuni me nā loli wikiwiki o ka mahana a kūpono hoʻi no nā kaiapuni haʻalulu wela.

ʻAʻohe emi ʻana i ka wā sintering:ʻAʻole ia e emi i ka wā o ke kaʻina hana sintering, a ʻaʻohe koena koʻikoʻi e hana ʻia e hoʻoulu ai i ka deformation a i ʻole ka haki ʻana o ka huahana. He kūpono ia no ka hoʻomākaukau ʻana i nā ʻāpana me nā ʻano paʻakikī a me ke kiko kiʻekiʻe.

(2) Nā Huahana Nui:

Nā mea hana lako o ka umu ahi:Hoʻohana nui ʻia no nā lako umu, loaʻa iā ia nā pono o ka mālama ʻana i ka ikehu, ka hoʻonui ʻana i ka nui o ka umu, ka hoʻopōkole ʻana i ke kaʻina hana ahi, ka hoʻomaikaʻi ʻana i ka pono hana o ka umu a me nā pono waiwai kiʻekiʻe.

Nā ʻūpā puhi:Hiki ke hoʻohana ʻia ma ke ʻano he poʻo nozzle kuni a kūpono hoʻi no nā wahi mahana kiʻekiʻe.

Nā paipu hoʻomehana kukuna seramika:Hoʻohana kēia mau paipu hoʻomehana i ke kūpaʻa wela kiʻekiʻe a me ke kūpaʻa ʻana i ka pala o ka silicon carbide recrystallized a kūpono no nā noi ʻoihana wela kiʻekiʻe like ʻole.

Nā paipu pale ʻāpana:ʻOi loa aku i loko o nā umu lewa, hoʻohana ʻia nā huahana silicon carbide i hoʻopili hou ʻia ma ke ʻano he mau paipu pale ʻāpana me ke kūpaʻa maikaʻi i ka mahana kiʻekiʻe a me ka palaho.

Nā kino pamu wela kiʻekiʻe, nā impellers pamu, nā bearings, nā hale mīkini:Ma nā kahua o nā kaʻa, nā ʻoihana aerospace a me nā ʻoihana koa, hana ʻia nā mea silicon carbide i hoʻopili hou ʻia i nā kino pamu wela kiʻekiʻe, nā impellers pamu, nā bearings a me nā hale mīkini, a pēlā aku, e hoʻohana ana i ko lākou kūpaʻa wela kiʻekiʻe, kūpaʻa waikawa a me ka alkali a me ke kūpaʻa ʻana i ka ʻaʻahu.

Nā Kiʻi kikoʻī

Nā ʻāpana i hoʻohālikelike ʻia me Silicon Carbide

Papa Silicon Carbide

ʻŌwili Silicon Carbide

Kukui Silicon Carbide

Nā Paipu Hoʻomalu Silicon Carbide

Nā Lako Uila

ʻO ka Silicon Carbide Sagger

Keʻena hoʻoheheʻe Silicon Carbide

Papa Silicon Carbide

Mea hoʻoheheʻe ʻaila Silicon Carbide

Paipu Silicon Carbide

Mea puhi ʻāʻī Silicon Carbide

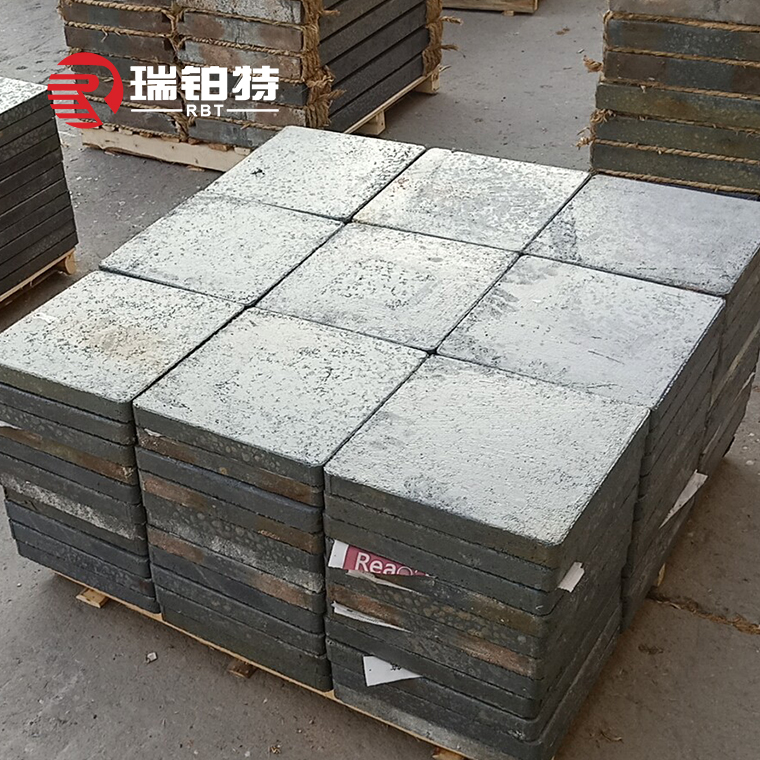

4. Nā huahana silicon carbide i hoʻopaʻa ʻia me ka nitride silikona(Nā Huahana NSiC)

ʻO nā huahana silicon carbide i hoʻopaʻa ʻia me ka silicon nitride he mea ia i hana ʻia ma ka hoʻohui ʻana i ka SiC aggregate i ka pauka silicon ʻoihana, e hana ana me ka naikokene ma ke ana wela kiʻekiʻe e hana i ka Si3N4 a hui pū me nā ʻāpana SiC.

(1) Nā ʻano:

Paʻakikī kiʻekiʻe:ʻO ka paʻakikī Mohs o nā huahana silicon carbide i hoʻopaʻa ʻia me ka silicon nitride ma kahi o 9, ʻo ka lua wale nō ia ma hope o ke daimana, a he mea ia me ka paʻakikī kiʻekiʻe ma waena o nā mea ʻaʻole metala.

Ka ikaika o ka mahana kiʻekiʻe:Ma nā mahana kiʻekiʻe o 1200-1400 ℃, ʻaneʻane ʻaʻole i loli ka ikaika a me ka paʻakikī o ka mea, a hiki i ka mahana palekana kiʻekiʻe loa ke piʻi i 1650-1750 ℃.

?

Paʻa wela:He liʻiliʻi kona coefficient hoʻonui wela a me ke alakaʻi wela kiʻekiʻe, ʻaʻole maʻalahi ka hoʻoulu ʻana i ke kaumaha wela, loaʻa iā ia ke kūpaʻa haʻalulu wela maikaʻi a me ke kū'ē ʻana i ke kolo, a kūpono no nā wahi anu loa a me nā wahi wela.

Paʻa kemika:He kūpaʻa ia i ka pala a me ka pale ʻana i ka oxidation, a hiki ke noho paʻa i nā ʻano kemika like ʻole.

Ke kū'ē'ē o ke komo:He kūpaʻa maikaʻi kona i ka ʻaʻahu ʻana a kūpono ia no nā noi ʻoihana like ʻole me ka ʻaʻahu koʻikoʻi.

(2) Nā Huahana Nui:

Nā pōhaku paʻa ʻole:hoʻohana nui ʻia i loko o ka alumini electrolytic, nā umu pahū hao, nā umu arc i hoʻoheheʻe ʻia a me nā ʻoihana ʻē aʻe, me nā ʻano o ke kūpaʻa wela kiʻekiʻe, ke kūpaʻa i ka corrosion, a me ke kūpaʻa i ka erosion.

Nā lako umu:hoʻohana ʻia no nā huila wili seramika, ka porcelain uila kiʻekiʻe-voltage, nā umu ʻoihana, a me nā mea ʻē aʻe, me ka hiki ke lawe i ka ukana maikaʻi a me ke kūpaʻa wela kiʻekiʻe.

Nā huahana ʻano kūikawā:hoʻohana ʻia i ka hoʻolei metallurgical non-ferrous, ka mana wela, nā umu arc i hoʻoheheʻe ʻia a me nā ʻoihana ʻē aʻe, me nā ʻano o ke kūpaʻa ʻana i ke kapa a me ke kūpaʻa wela kiʻekiʻe.

Nā ʻāpana refractory:me nā ʻōmole pale thermocouple, nā ʻōmole riser, nā ʻūlū hoʻomehana, a me nā mea ʻē aʻe, i hoʻohana ʻia i nā umu wela kiʻekiʻe a me nā lewa like ʻole, me ka conductivity thermal kiʻekiʻe a me ke kūpaʻa i ka corrosion.

Nā Kiʻi kikoʻī

Papa ʻAno Silicon Carbide

Papa ʻAno Silicon Carbide

Papa ʻAno Silicon Carbide

Papa ʻAno Silicon Carbide

Papa ʻAno Silicon Carbide

Nā Paipu Hoʻoheheʻe Silicon Carbide

Paipu Silicon Carbide

Papa ʻAno Silicon Carbide

Nā ʻāpana i hoʻohālikelike ʻia me Silicon Carbide

Nā Paipu Hoʻomalu Silicon Carbide

Papa Silicon Carbide

Nā Piliki Silicon Carbide

5. Nā huahana silicon carbide i hoʻopaʻa ʻia me ka oxide

Hana ʻia nā huahana silicon carbide i hoʻopaʻa ʻia me ka oxide ma ke kāwili ʻana i nā ʻāpana silicon carbide me ka pauka oxide (e like me ka silicon dioxide a i ʻole mullite), kaomi ʻana a me ka sintering ma ke ana wela kiʻekiʻe. ʻO kona ʻano, ʻo ia ka wā o ke kaʻina sintering a me ka hoʻohana ʻana, ua kāʻei ʻia ka ʻili oxide ma luna o nā ʻāpana silicon carbide, kahi e hoʻomaikaʻi nui ai i ke kūpaʻa oxidation a me ka ikaika wela kiʻekiʻe.

Loaʻa iā ia nā ʻano o ka ikaika flexural wela kiʻekiʻe, ke kūpaʻa haʻalulu wela maikaʻi, ka conductivity wela kiʻekiʻe, ke kūpaʻa ʻana i ka ʻaʻahu a me ke kūpaʻa ikaika i nā ʻano ʻino like ʻole o ka lewa, a he mea mālama ikehu kūpono ia no nā umu ʻoihana.

(2) Nā Huahana Nui:

Nā huahana silicon carbide i hoʻopaʻa ʻia me ka silicon dioxide:Hoʻohana kēia huahana i ka silicon dioxide (SiO2) ma ke ʻano he pae hoʻopaʻa. ʻO ka maʻamau, 5% ~ 10% o ka pauka silicon dioxide a i ʻole ka pauka quartz i hui pū ʻia me nā ʻāpana silicon carbide (SiC). I kekahi manawa hoʻohui ʻia kahi flux. Ma hope o ke kaomi ʻana a me ka hoʻokumu ʻana, ua puhi ʻia i loko o kahi umu ahi maʻamau. ʻO kona ʻano, ʻo ia ka wā o ke ahi ʻana a me ke kaʻina hana hoʻohana, ua kāʻei ʻia ka ʻili silicon dioxide ma luna o nā ʻāpana silicon carbide, kahi e hoʻomaikaʻi nui ai i ke kūpaʻa oxidation a me ka ikaika wela kiʻekiʻe. Hoʻohana nui ʻia kēia huahana i nā papa umu ahi no ke ahi ʻana i ka porcelain (>1300 ℃), a ʻoi aku kona ola lawelawe ma mua o

ua pāpālua ʻia ka nui o nā huahana silicon carbide i hoʻopaʻa ʻia me ka lepo.

Nā huahana silicon carbide i hoʻopaʻa ʻia ʻo Mullite:Hoʻohui kēia huahana i ka pauka α-Al2O3 a me ka pauka silicon dioxide i nā mea hana silicon carbide. Ma hope o ke kaomi ʻana a me ka hana ʻana, ua hui pū ʻia ʻo Al2O3 a me SiO2 e hana i ka mullite i ka wā o ke kaʻina hana sintering. I ka wā e hoʻohana ai, ʻo ka silicon dioxide i hana ʻia e ka oxidation o ka silicon carbide e hana hapa i ka mullite me Al2O3. Loaʻa i kēia mea ke kūpaʻa haʻalulu wela maikaʻi a hoʻohana nui ʻia i ka hana ʻana i nā saggers porcelain a me nā papa.

Nā Kiʻi kikoʻī

Papa Silicon Carbide

Nā Piliki Silicon Carbide

Papa Silicon Carbide

Paipu Microcrystalline SiC

Papa Microcrystalline SiC

Papa Microcrystalline SiC

ʻIkepili Hui

ʻO Shandong Robert New Material Co., Ltd.Aia ma ke kūlanakauhale ʻo Zibo, ka moku ʻo Shandong, Kina, he kahua hana mea refractory. He ʻoihana hou mākou e hoʻohui i ka noiʻi a me ka hoʻomohala ʻana, ka hana ʻana, ke kūʻai aku ʻana, ka hoʻolālā a me ke kūkulu ʻana i ka umu, ka ʻenehana, a me ka hoʻokuʻu aku i nā mea refractory. Loaʻa iā mākou nā lako piha, nā ʻenehana holomua, ka ikaika loea ikaika, ka maikaʻi o ka huahana, a me ka inoa maikaʻi. Uhi kā mākou hale hana ma mua o 200 ʻeka a ʻo ka hopena makahiki o nā mea refractory i hoʻohālikelike ʻia he 30000 tons a ʻo nā mea refractory i hoʻohālikelike ʻole ʻia he 12000 tons.

ʻO kā mākou huahana nui o nā mea refractory:nā mea kūpaʻa alkaline; nā mea kūpaʻa silicon alumini; nā mea kūpaʻa ʻano ʻole; nā mea kūpaʻa wela insulation; nā mea kūpaʻa kūikawā; nā mea kūpaʻa hana no nā ʻōnaehana hoʻolei mau.

Nā Nīnau i Nīnau Pinepine ʻia

Pono kōkua? E kipa aku i kā mākou mau kahua kākoʻo no nā pane i kāu mau nīnau!

He mea hana maoli mākou, ua loea kā mākou hale hana i ka hana ʻana i nā mea refractory no nā makahiki he 30 a ʻoi. Hoʻohiki mākou e hāʻawi i ke kumukūʻai maikaʻi loa, ka lawelawe mua a me ka lawelawe ma hope o ke kūʻai aku.

No kēlā me kēia kaʻina hana, loaʻa iā RBT kahi ʻōnaehana QC piha no ka hoʻohuihui kemika a me nā waiwai kino. A e hoʻāʻo mākou i nā waiwai, a e hoʻouna ʻia ka palapala hōʻoia maikaʻi me nā waiwai. Inā he mau koi kūikawā kāu, e hoʻāʻo mākou i ka maikaʻi loa e hoʻokō iā lākou.

Ma muli o ka nui, ʻokoʻa ka manawa hoʻouna. Akā ke hoʻohiki nei mākou e hoʻouna koke me ka maikaʻi i hōʻoia ʻia.

ʻOiaʻiʻo, hāʻawi mākou i nā laʻana manuahi.

ʻAe, ʻoiaʻiʻo, ua ʻoluʻolu ʻia ʻoe e kipa i ka hui ʻo RBT a me kā mākou huahana.

ʻAʻohe palena, hiki iā mākou ke hāʻawi i ka manaʻo maikaʻi loa a me ka hoʻonā e like me kou kūlana.

Ua hana mākou i nā mea refractory no nā makahiki he 30 a ʻoi, loaʻa iā mākou ke kākoʻo loea ikaika a me ka ʻike waiwai, hiki iā mākou ke kōkua i nā mea kūʻai aku e hoʻolālā i nā kilns like ʻole a hāʻawi i ka lawelawe hoʻokahi.