Palekana Waapa Silicon Carbide

Māhele Huahana

1. ʻO nā huahana carbide silikona i hoʻopaʻa ʻia (RBSiC Products)

ʻO Reaction bonded silicon carbide (RBSiC) kahi mea hana seramika ʻenehana holomua e hoʻopuka ana i kahi pae hoʻopaʻa silicon carbide ma o ka hana ʻana i ke kalapona manuahi me ka silika wai ma lalo o nā kūlana wela kiʻekiʻe. ʻO kāna mau mea maʻamau, ʻo ia ka silicon carbide (SiC) matrix a me ka manuahi manuahi (Si). Hāʻawi ka mea mua i nā waiwai mechanical maikaʻi loa, ke kūpaʻa a me ke kūpaʻa wela kiʻekiʻe,

ʻoiai ka mea hope e hoʻopiha i nā pores ma waena o nā ʻāpana carbide silicon e hoʻonui i ka paʻa a me ka paʻa pono o ka mea.

(1) Nā ʻano:

Paʻa wela kiʻekiʻe:ʻO ka mahana hana kiʻekiʻe loa he 1350 ℃.

ʻAʻahu kūpaʻa a me ka corrosion:He kūpono no nā kūlana hana koʻikoʻi o ka wela kiʻekiʻe, ka waikawa, ka alkali a me ka metala hoʻoheheʻe. ?

ʻO ka hoʻokō wela kiʻekiʻe a me ka helu hoʻonui haʻahaʻa haʻahaʻa:ʻO ke kiʻekiʻe o ka conductivity thermal e like me 120-200 W/(m·K), a ʻo ka helu hoʻonui wela he 4.5 × 10⁻⁶ K⁻¹ wale nō, kahi e pale pono ai i ka haki ʻana a me ka luhi wela. ?

Anti-oxidation:Hoʻokumu ʻia kahi papa pale silica paʻa ma luna o ka ʻili i ka wela kiʻekiʻe e hoʻonui i ke ola lawelawe.

(2) Nā huahana nui:

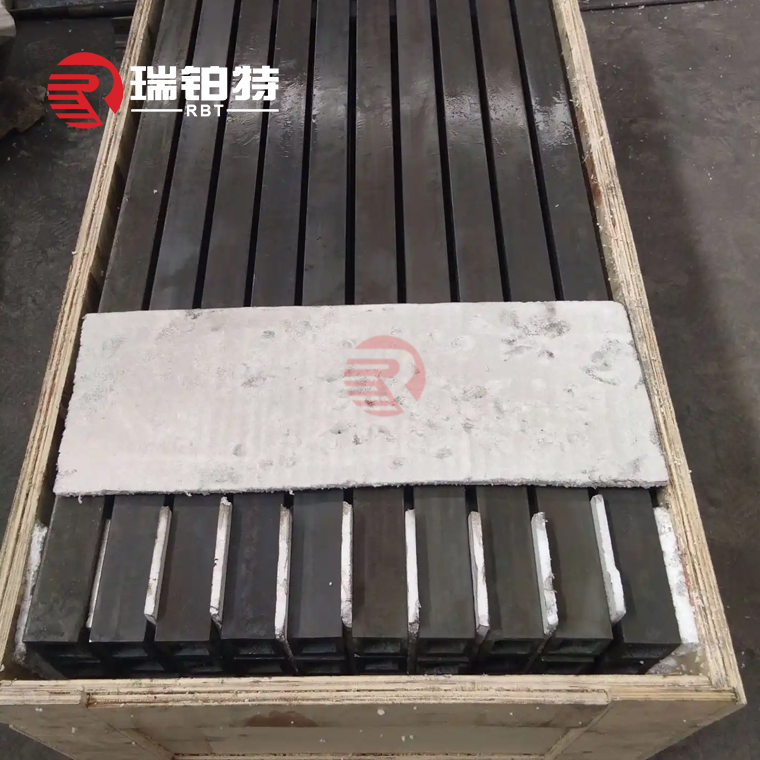

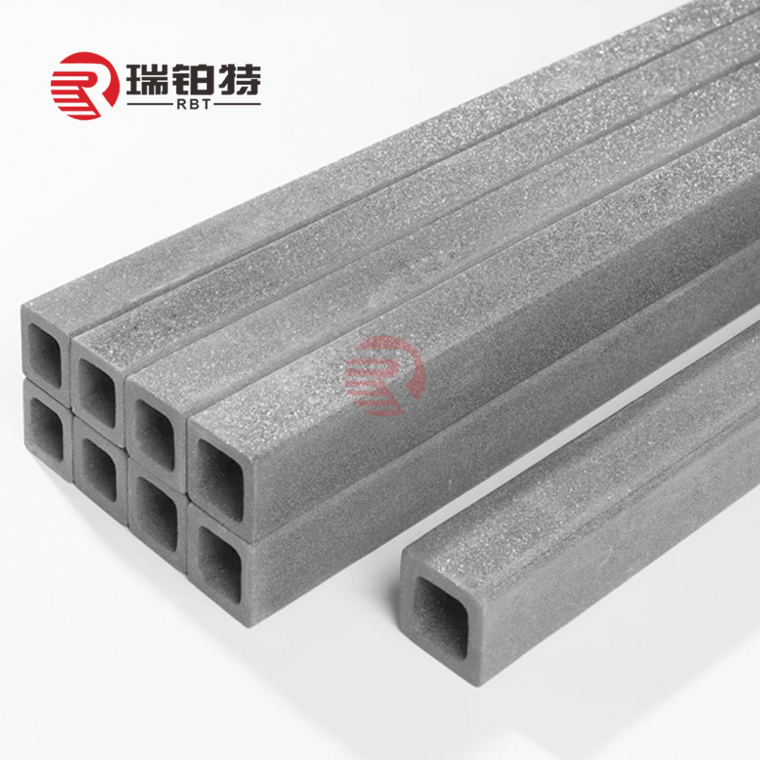

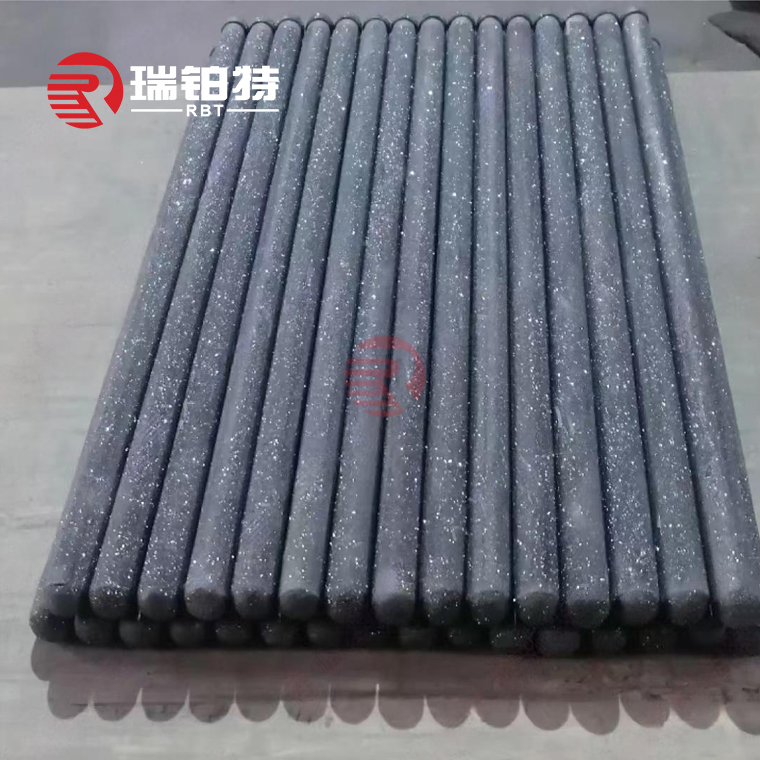

?ʻO ka lāʻau Silicon carbide:hoʻohana ʻia no ka hoʻokumu ʻana i ka ukana o nā kiln tunnel, shuttle kilns a me nā kiln ʻoihana ʻē aʻe, me ke kūpaʻa wela kiʻekiʻe.

?

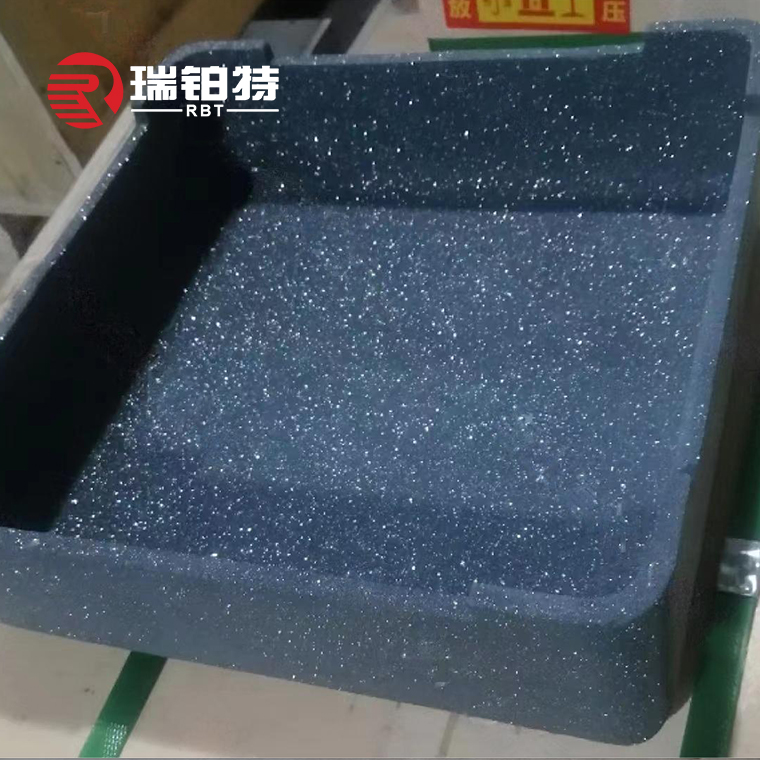

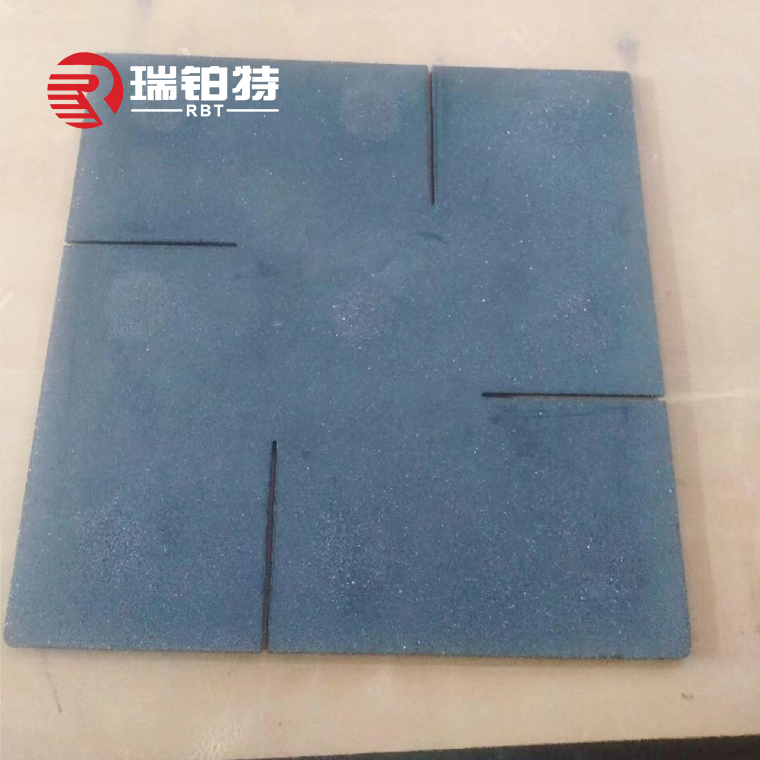

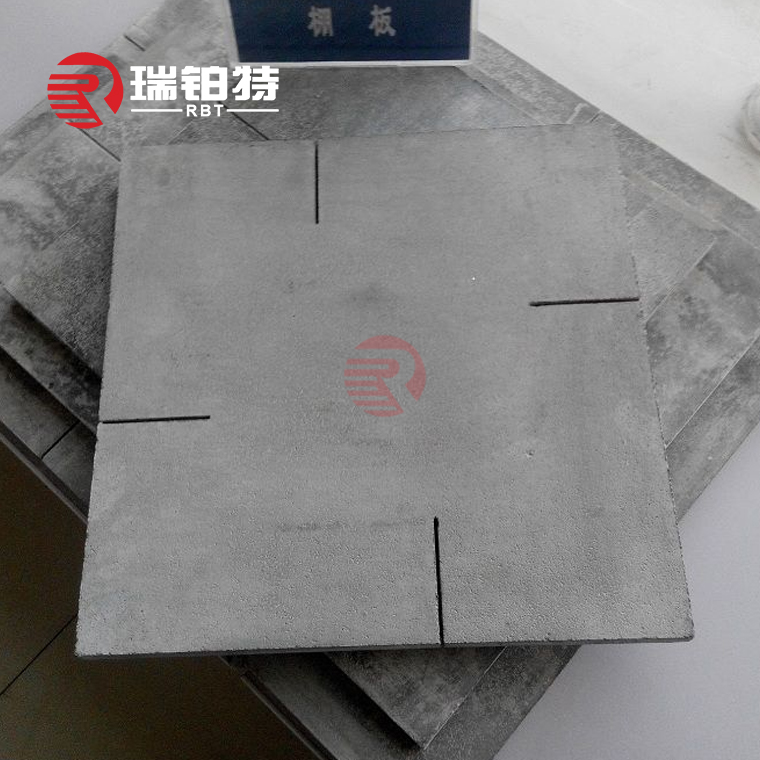

ʻO ka pā kila silikoni:hoʻohana ʻia no nā mea refractory i nā kiln, me nā ʻano o ka hoʻopaʻa ʻana o oxide. ?

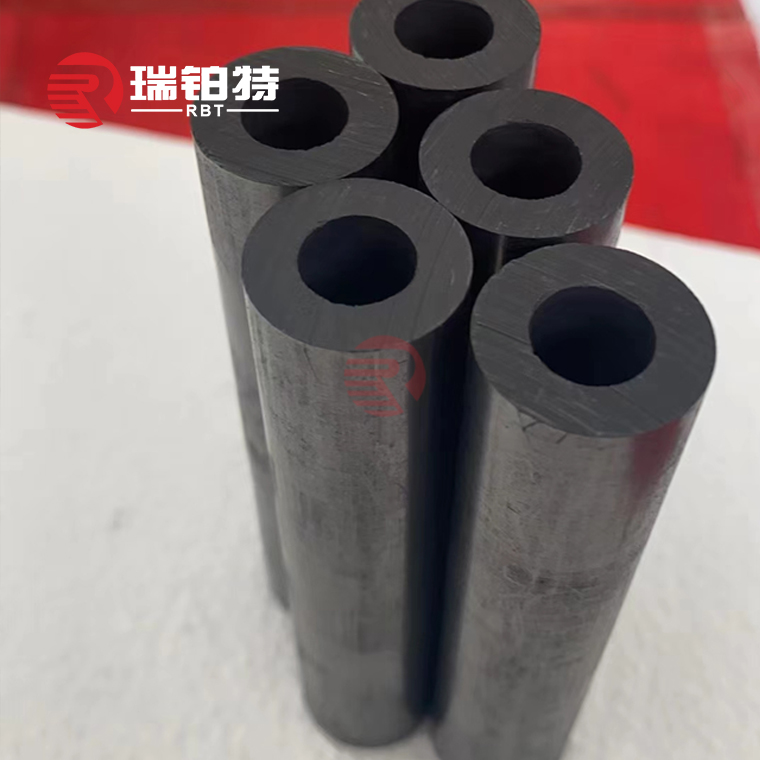

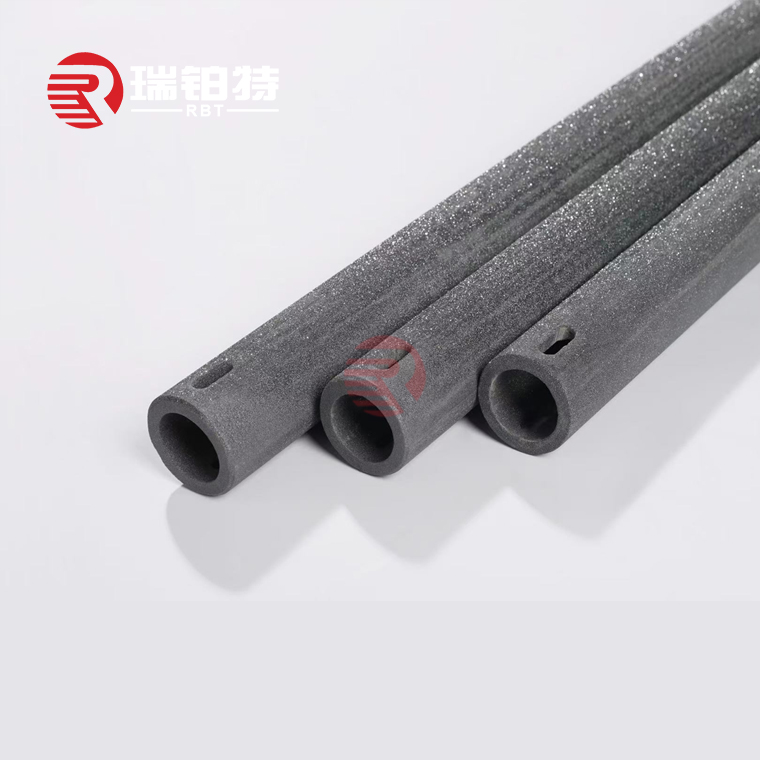

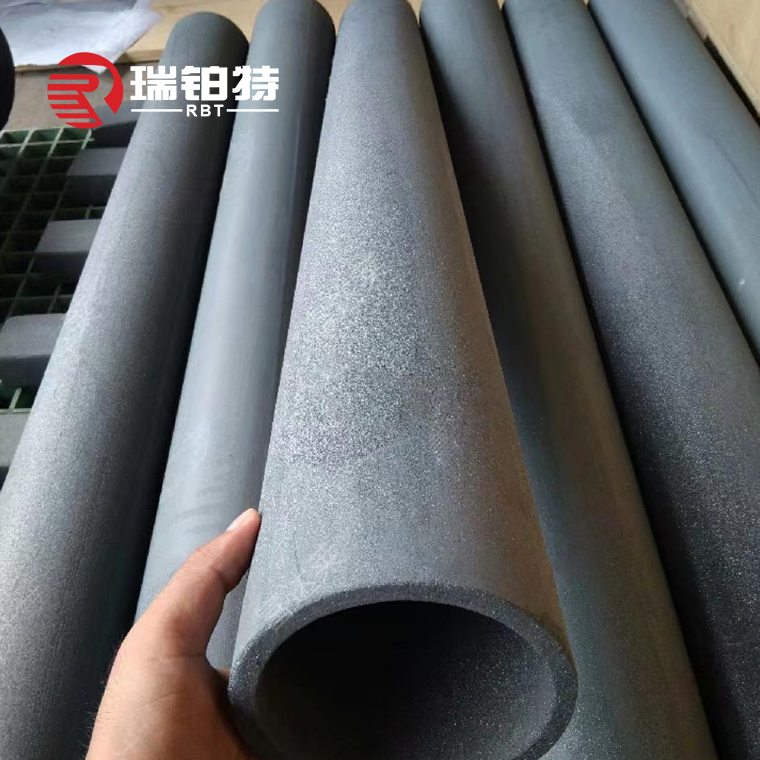

ʻO ka paipu Silicon carbide:hoʻohana ʻia no nā paipu a me nā pahu i nā ʻano wela wela. ?

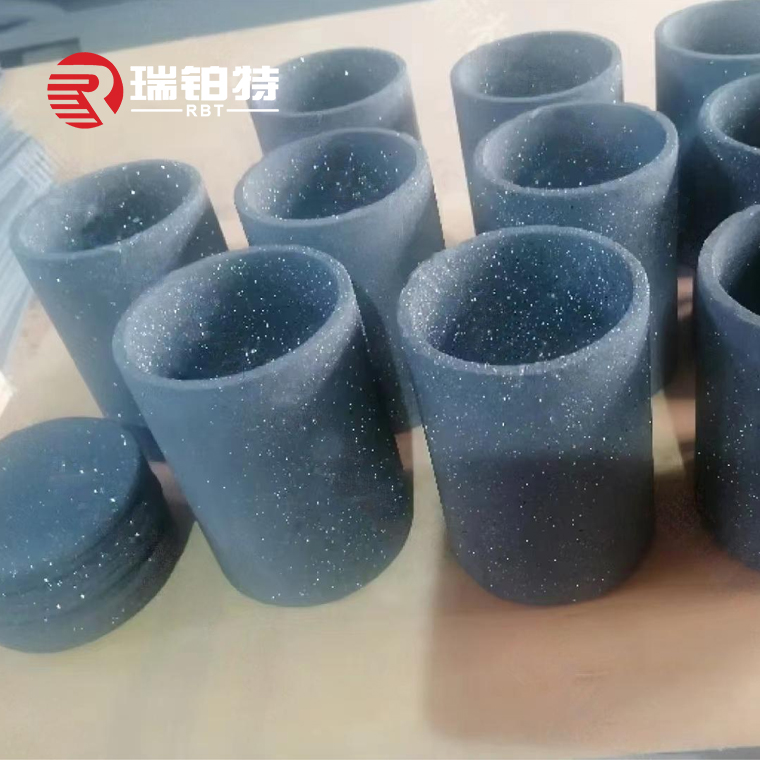

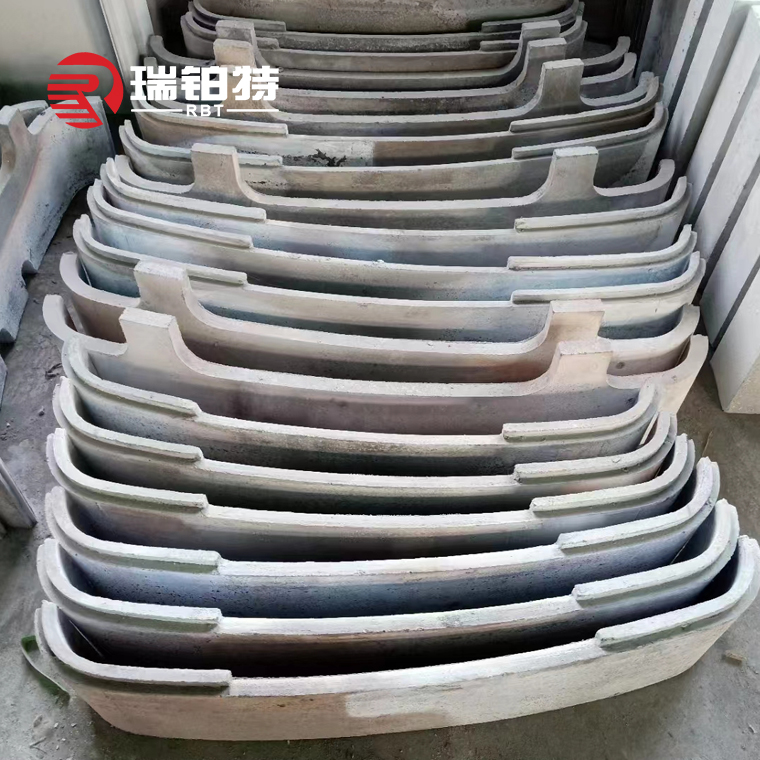

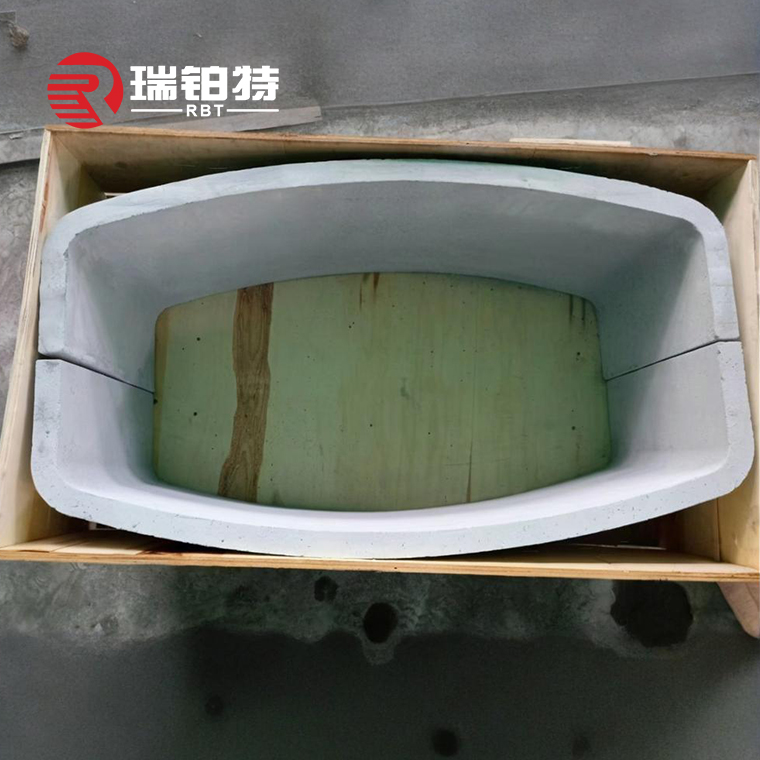

ʻO ke kīʻaha Silicon carbide a me ka sagger:hoʻohana ʻia no ka hoʻoheheʻe wela kiʻekiʻe a me ka mālama ʻana i nā mea. ?

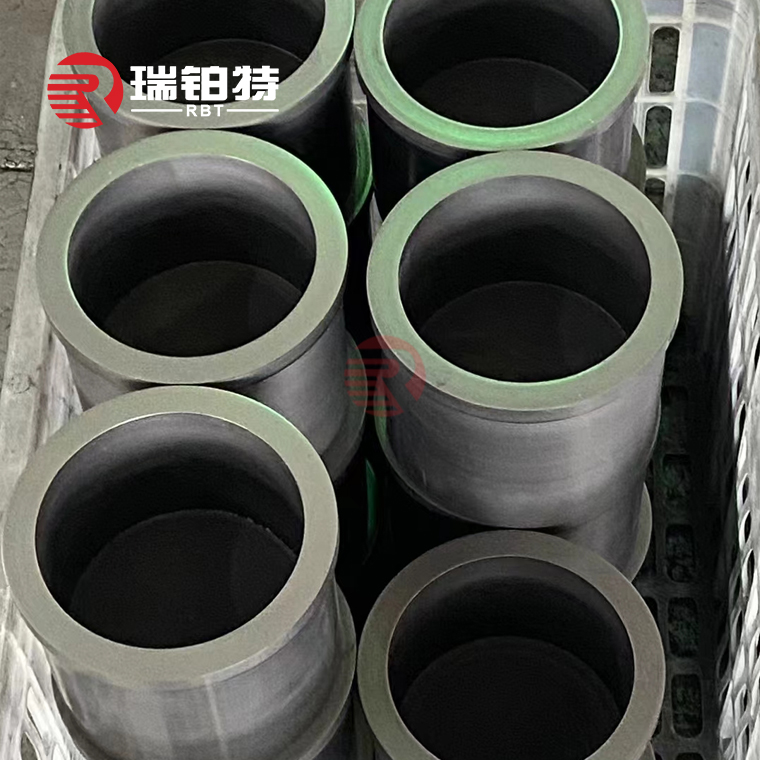

Silicon carbide sila apo apo:hoʻohana nui ʻia i ka hana o nā kaʻa, aerospace a me ka ʻoihana kemika, a hiki ke mālama i ka hana hoʻopaʻa paʻa pono i ke kiʻekiʻe kiʻekiʻe a me ke kaomi kiʻekiʻe. ?

Silicon carbide roller:hoʻohana ʻia no nā kiln roller, me nā hiʻohiʻona o ka anti-oxidation, ka ikaika flexural kiʻekiʻe a me ke ola lawelawe lōʻihi. ?

ʻO nā paipu hoʻoluʻu Silicon carbide:hoʻohana ʻia no ka ʻāpana hoʻoluʻu o nā kiln roller, me ke kūpaʻa maikaʻi i ke kiʻekiʻe

anu a me ka wela. ?

Silicon carbide bunner nozzle:hoʻohana ʻia no nā ʻano aila, gas a me nā kiln ʻoihana ʻē aʻe, me nā hiʻohiʻona o ke anuanu a me ke kūpaʻa wela, ke kūpaʻa ʻana, ke kūpaʻa wela kiʻekiʻe, etc. ?

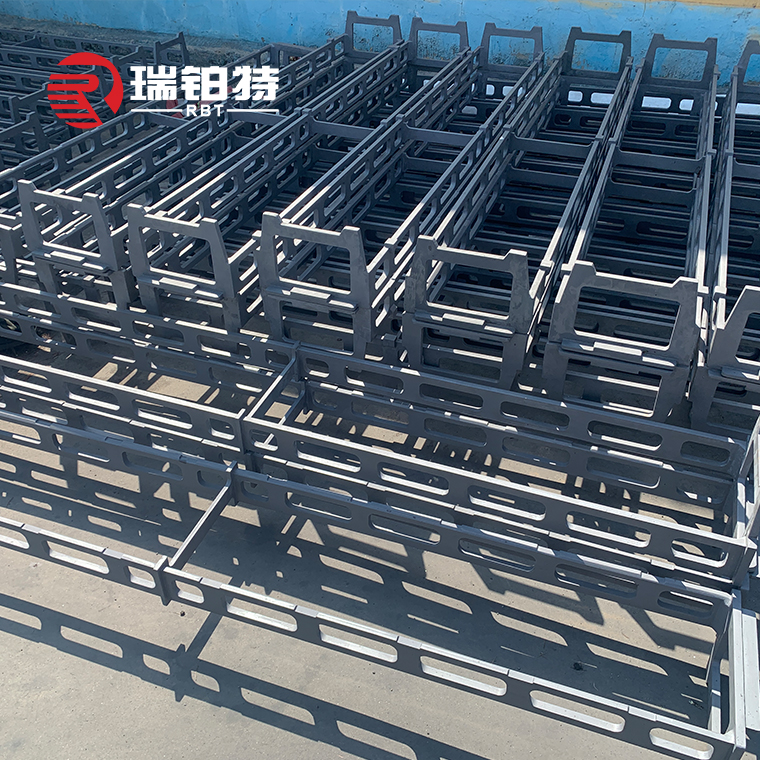

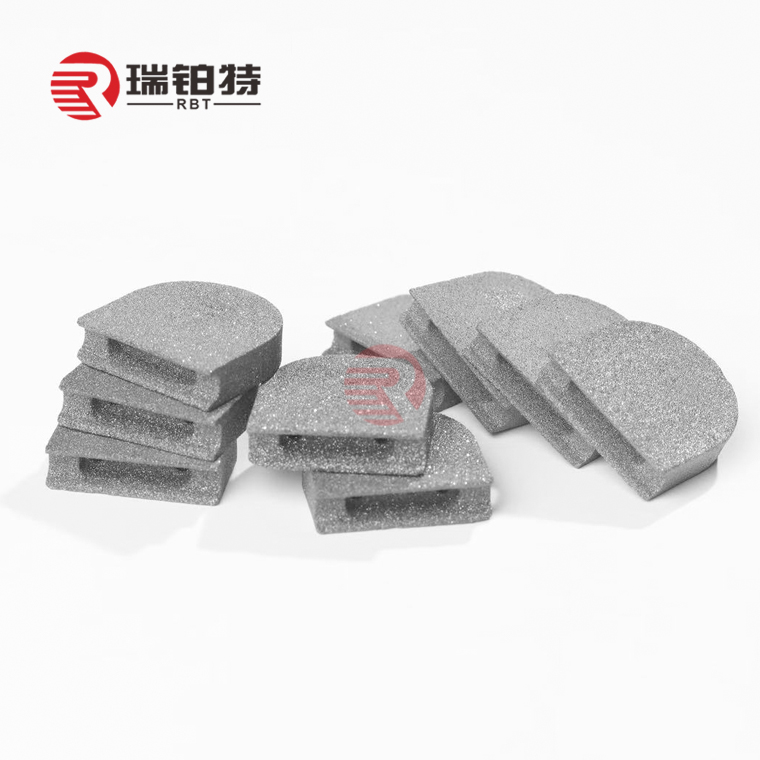

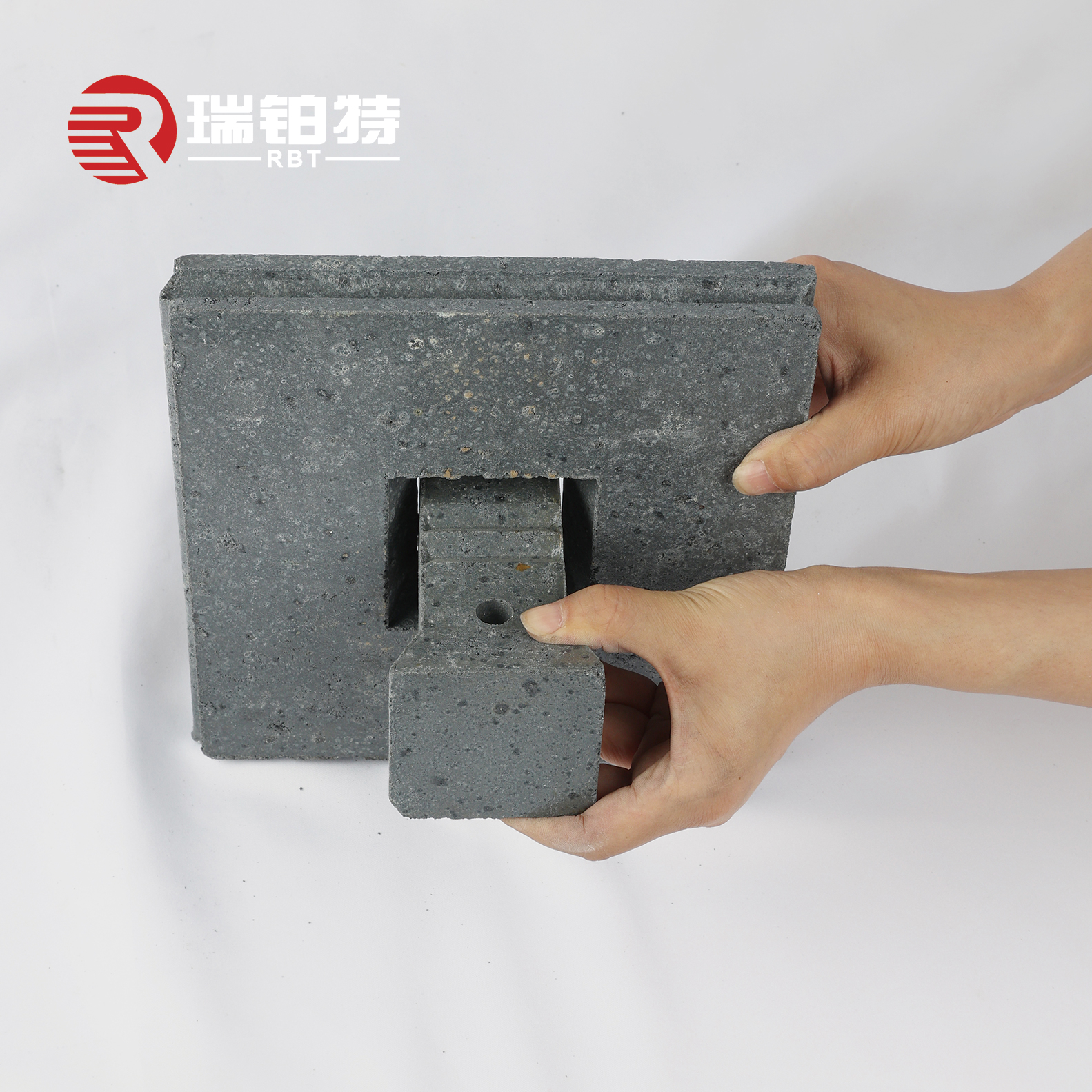

Nā ʻāpana ʻano kūikawā kūikawā:ʻO ka hana maʻamau o nā ʻāpana like ʻole e like me nā pono o ka mea kūʻai aku, e like me nā papa iʻa, nā koʻokoʻo e kau ana, nā ʻāpana kākoʻo, etc.

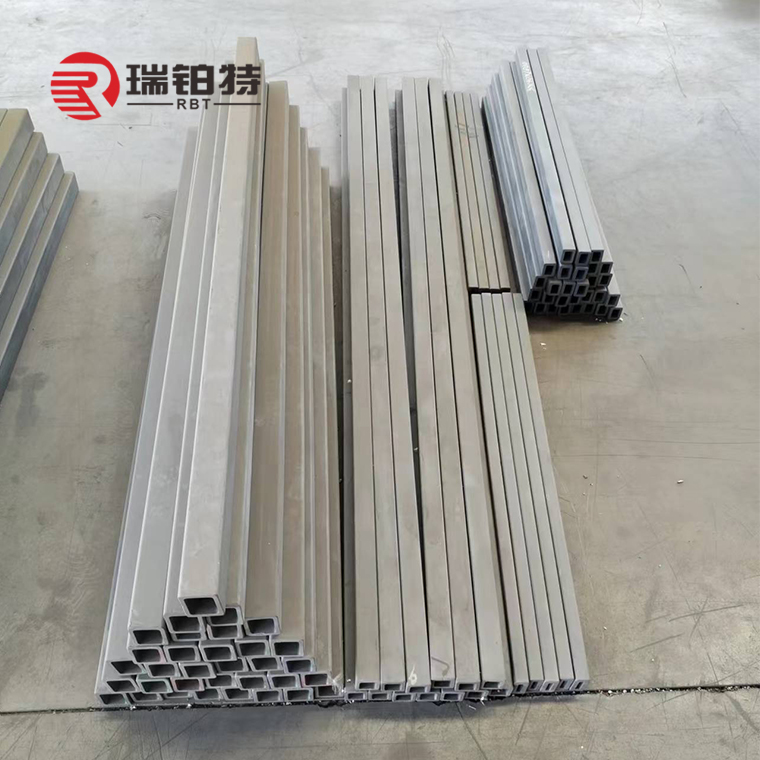

Nā kiʻi kikoʻī

ʻO ka lāʻau Silicon Carbide

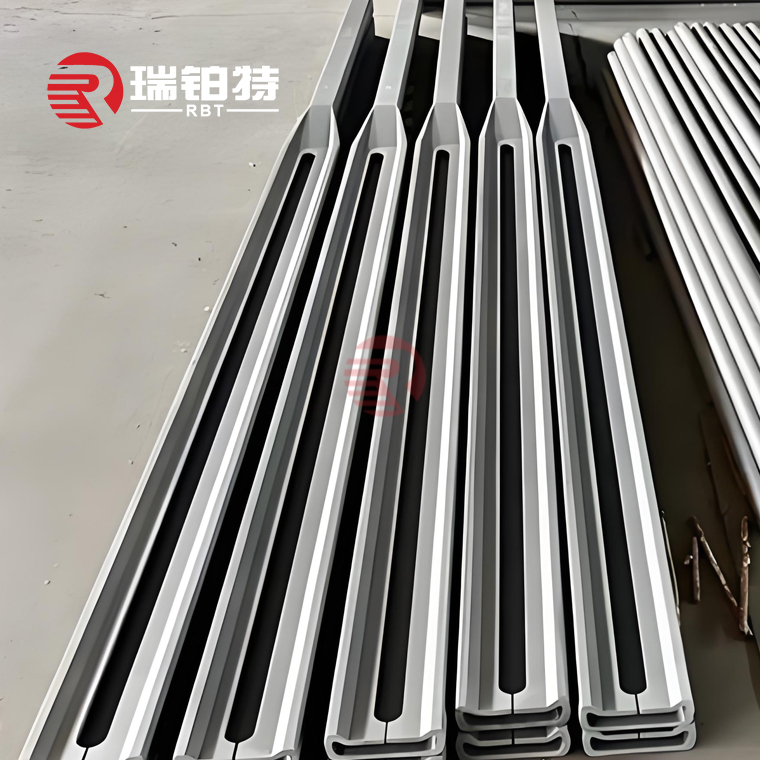

ʻO Silicon Carbide Cantilever hoe

Nozzle Kapili Silika

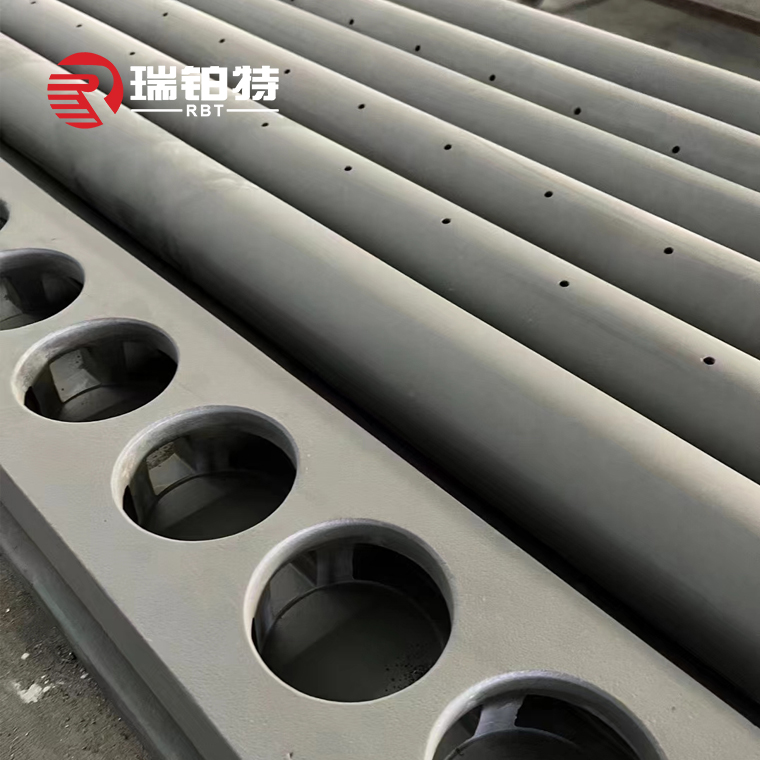

Paipu Puka Silicon Carbide

Paipu Hooluu Silicon Carbide

Nozzle Kapili Silika

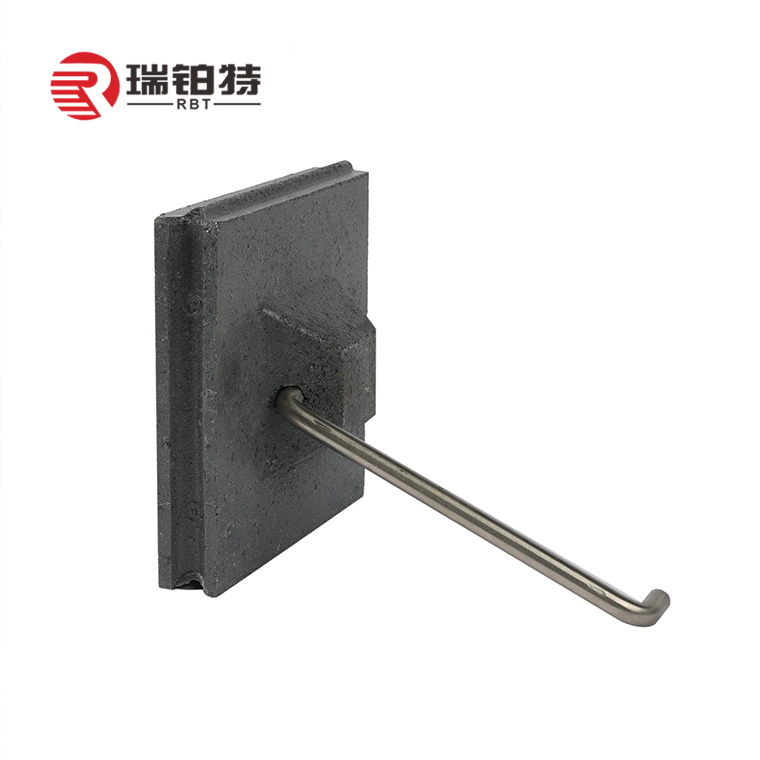

Palekana Waapa Silicon Carbide

Lining pale ʻaʻahu

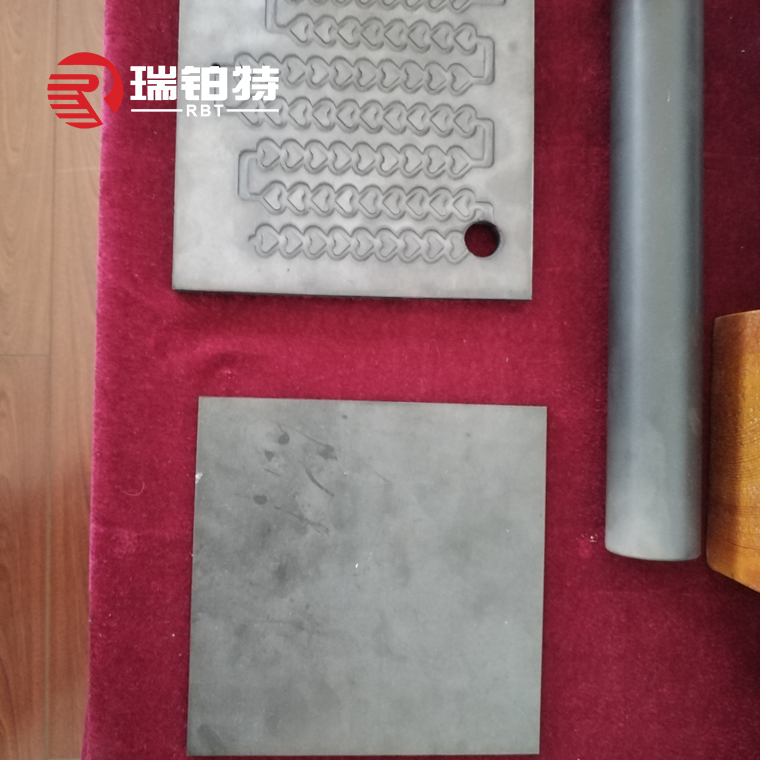

Waapa Wafer Silicon Carbide

Huahana Huahana

| Nā huahana RBSiC(SiSiC). | ||

| 'ikamu | Unite | ʻIkepili |

| Max Mahana o ka noi | ℃ | ≤1350 |

| ʻO ka mānoanoa | g/cm3 | ≥3.02 |

| Wehe Porosity | % | ≤0.1 |

| Kulou ikaika | Mpa | 250(20 ℃); 280(1200 ℃) |

| Modulus o Elastictiy | Gpa | 330(20 ℃); 300(1200 ℃) |

| ʻO ka hoʻoili wela | W/mk | 45(1200 ℃) |

| ʻO ka hoʻonui wela wela | K-1*10-6 | 4.5 |

| Ka paakiki o Moh | | 9.15 |

| Hōʻoiaʻiʻo ʻAkaʻikaʻi | | Maikaʻi |

2. ʻO nā huahana silikon carbide kaomi ʻole ʻia (SSiC Products)

ʻO nā huahana silicon carbide Pressureless sintered he ʻano mea ʻenehana kiʻekiʻe i hoʻomākaukau ʻia e ke kaʻina sintering pressureless. ʻO kāna mea nui he silicon carbide (SiC), a ua hoʻohui ʻia kekahi hapa o nā mea hoʻohui. Ma o ka ʻenehana seramika kiʻekiʻe, ua hana ʻia i loko o ka porous, ʻole, a me ke koʻikoʻi ʻole i nā ceramics kiʻekiʻe.

(1) Nā ʻano:

Kūleʻa wela kiʻekiʻe:hoʻohana maʻamau ma 1800 ℃;

Kiʻekiʻe thermal conductivity:like me ka wela o ka graphitemea waiwai;

Paʻakiki kiʻekiʻe:ʻO ka paʻakikī ka lua ma mua o ke daimana a me ka cubic boron nitride;

ʻO ke kūpaʻa ʻino:ʻO ka waika ikaika a me ka alkali ikaika ʻaʻohe corrosion iā ia, a ʻoi aku ka maikaʻi o kona pale ʻana ma mua o ka tungsten carbide a me ka alumini oxide;

Kaumaha māmā:mānoanoa 3.10g/cm3, kokoke i ka alumini;

ʻAʻohe deformation:liʻiliʻi liʻiliʻi hoʻonui wela wela,

Kūleʻa i ka haʻalulu wela:hiki i ka mea ke kū i ka hoʻololi wikiwiki ʻana i ka wela, ka haʻalulu wela, ka hoʻoluʻu wikiwiki a me ka hoʻomehana, a paʻa ka hana.

(2) Nā huahana nui:

Nā apo sila:Hoʻohana pinepine ʻia nā huahana silicon carbide pressureless no ka hana ʻana i nā apo hoʻopaʻa paʻa ʻole a me ka corrosion-resistant sealing apo a me nā bearings sliding. ?

Nā ʻāpana mīkini:Me nā bearings wela kiʻekiʻe, nā sila mechanical, nozzles, pneumatic valves, pump kino, fixtures, etc.

Nā mea hana kemika:Hoʻohana ʻia no ka hana ʻana i nā paipu pale ʻino, nā pahu mālama, nā reactors a me nā sila. ?

Nā mea uila:I ka ʻoihana mana, hoʻohana ʻia ka pressureless sintered silicon carbide no ka hana ʻana i nā pale pale wela kiʻekiʻe, nā mea hoʻomehana uila a me nā hoʻololi kiʻekiʻe-voltage. ?

Nā lako kiln:E like me nā papa hana haʻahaʻa, nā wili, nā nozzles lapalapa, nā paipu hoʻoluʻu, a me nā mea ʻē aʻe i loko o nā kiln tunnel, nā kiln shuttle a me nā kiln ʻoihana ʻē aʻe. ?

Nā kiʻi kikoʻī

apo siliki karbida sila

Paipu Silicon Carbide

ʻO nā Liners Silicon Carbide

ʻO ka lāʻau Silicon Carbide

Pāpaʻa Kapili Silika

ʻO ka pahu hoʻoheheʻe Silicon Carbide

Huahana Huahana

| Nā huahana SSiC | ||

| 'ikamu | Unite | Ka hopena |

| ʻoʻoleʻa | HS | ≥115 |

| Ka helu Porosity | % | <0.2 |

| ʻO ka mānoanoa | g/cm3 | ≥3.10 |

| Ka ikaika hoʻopili | Mpa | ≥2500 |

| Kulou ikaika | Mpa | ≥380 |

| Coefficient o ka Hoonui | 10-6/℃ | 4.2 |

| Maʻiʻo o SiC | % | ≥98 |

| Kuokoa Si | % | <1 |

| Elastic Modulus | Gpa | ≥410 |

| Max Mahana o ka noi | ℃ | 1400 |

3. Huahana karbida silikona hou (RSiC Products)

ʻO Recrystallized Silicon Carbide Products kahi huahana refractory i hana ʻia me ka silicon carbide maʻemaʻe kiʻekiʻe e like me ka mea maka. ʻO kāna hiʻohiʻona nui ʻaʻohe ʻāpana lua a ua haku ʻia ʻo 100% α-SiC.

(1) Nā ʻano:

Paʻakiki kiʻekiʻe:ʻO kona paʻakikī ka lua wale nō i ke daimana, a he kiʻekiʻe loa ka ikaika mechanical a me ka rigid. ?

Kūleʻa wela kiʻekiʻe:Hiki iā ia ke mālama i ka hana paʻa i ke kaiapuni wela kiʻekiʻe a kūpono i ka pae wela o 1350 ~ 1600 ℃. ?

Ke kū'ē i ka corrosion ikaika:Loaʻa iā ia ka pale corrosion kiʻekiʻe i nā ʻano media like ʻole a hiki ke mālamanā waiwai mechanical no ka manawa lōʻihi i nā ʻano ʻano corrosive. ?

ʻO ke kūpaʻa oxidation maikaʻi:Loaʻa iā ia ka pale oxidation maikaʻi a hiki ke hana paʻa i nā wela kiʻekiʻe. ?

Kūleʻa haʻalulu wela maikaʻi:Hana maikaʻi ʻo ia i kahi kaiapuni me ka wikiwiki o ka hoʻololi ʻana i ka mahana a kūpono i nā wahi haʻalulu. ?

ʻAʻohe hōʻemi i ka wā o ka sintering:ʻAʻole ia e emi i ka wā o ke kaʻina hana sintering, a ʻaʻohe koena koʻikoʻi e hana ʻia i mea e hoʻololi ai a haki paha i ka huahana. He kūpono ia no ka hoʻomākaukau ʻana i nā ʻāpana me nā ʻano paʻakikī a me ka pololei.

(2) Nā huahana nui:

Nā lako hale kiln:Hoʻohana nui ʻia no nā lako kiln, loaʻa iā ia nā pōmaikaʻi o ka mālama ʻana i ka ikehu, hoʻonui i ka nui o ka kiln, hoʻopōkole i ka pōʻai ahi, hoʻomaikaʻi i ka hana hana kiln a me nā pono waiwai kiʻekiʻe. ?

Nā nozzles Bunner:Hiki ke hoʻohana ʻia e like me nā poʻo nozzle combustion a kūpono i nā wahi wela kiʻekiʻe. ?

ʻO nā paipu hoʻomehana hoʻoheheʻe ceramic:Hoʻohana kēia mau paipu hoʻomehana i ke kūpaʻa kiʻekiʻe o ka wela a me ka pale ʻana i ka corrosion o recrystallized silicon carbide a kūpono i nā noi ʻoihana wela kiʻekiʻe. ?

ʻO nā paipu pale ʻāpana:ʻOi loa i loko o nā umu lewa, hoʻohana ʻia nā huahana silicon carbide i hoʻohana ʻia e like me nā paipu pale ʻāpana me ka wela kiʻekiʻe a me ke kūpaʻa corrosion. ?

ʻO nā kino pauma wela kiʻekiʻe, nā impeller pump, nā bearings, nā hale mīkini:Ma nā kahua o nā kaʻa, aerospace a me nā ʻoihana koa, ua hana ʻia nā mea hana silicon carbide i loko o nā kino pauma kiʻekiʻe, pump impellers, bearings a me nā hale mīkini, etc. ?

Nā kiʻi kikoʻī

ʻO nā ʻāpana Silicon Carbide

Pāpaʻa Kapili Silika

ʻO ka huila Silicon Carbide

ʻO ka lāʻau Silicon Carbide

ʻO nā paipu pale silikoni

Lako Kiln

ʻO Silicon Carbide Sagger

ʻAiʻa Silicon Carbide

Pāpaʻa Kapili Silika

ʻO ka Lgniter Silicon Carbide

Paipu Silicon Carbide

Puhi Kapili Silika

4. ʻO nā huahana silicon carbide i hoʻopaʻa ʻia ʻo Silicon nitride (NSiC Products)

ʻO nā huahana silicon carbide i hoʻopaʻa ʻia ʻo Silicon nitride he mea i hoʻohui ʻia e ka hoʻohui ʻana i ka SiC aggregate i ka pauka silicon ʻoihana, e pane ana me ka nitrogen i ke kiʻekiʻe kiʻekiʻe e hana ai i ka Si3N4 a hui pū me nā ʻāpana SiC.

(1) Nā ʻano:

Paʻakiki kiʻekiʻe:ʻO ka paʻakikī Mohs o nā huahana silicon carbide i hoʻopaʻa ʻia ma kahi o 9, ʻelua wale nō i ke daimana, a he mea ʻoi aku ka paʻakikī ma waena o nā mea non-metallic. ?

Ka ikaika wela kiʻekiʻe:Ma nā mahana kiʻekiʻe o 1200-1400 ℃, ʻaʻole i loli ka ikaika a me ka paʻakikī o ka mea, a hiki i ka wela hoʻohana palekana ke hiki i 1650-1750 ℃.

?

Paʻa wela:He liʻiliʻi liʻiliʻi ka hoʻonui ʻana i ka wela a me ka conductivity thermal kiʻekiʻe, ʻaʻole maʻalahi ka hoʻoulu ʻana i ke koʻikoʻi wela, maikaʻi ke kūpaʻa haʻalulu maikaʻi a me ke kūpaʻa ʻana, a kūpono no nā wahi anuanu a wela. ?

Paʻa kemika:He kūpaʻa ka corrosion a me ka oxidation-resistant, a hiki ke noho paʻa i nā ʻano kemika. ?

ʻAʻahu kūʻē:Loaʻa iā ia ke kūpaʻa ʻaʻahu maikaʻi a kūpono i nā noi ʻoihana like ʻole me ka ʻaʻahu koʻikoʻi.

(2) Nā huahana nui:

ʻO nā pōhaku makamae:hoʻohana nui ʻia i ka alumini electrolytic, ironmaking blast furnaces, submerged arc furnaces a me nā ʻoihana ʻē aʻe, me nā hiʻohiʻona o ke kūpaʻa wela kiʻekiʻe, ka pale ʻana i ka corrosion, a me ke kūpaʻa erosion.

Lako Kiln:hoʻohana ʻia no nā huila wili seramika, porcelain uila kiʻekiʻe, nā kiln ʻoihana, a me nā mea ʻē aʻe, me ka hiki ke haʻi haʻahaʻa maikaʻi a me ke kūpaʻa wela kiʻekiʻe.

Nā huahana hoʻohālike kūikawā:hoʻohana ʻia i ka hoʻolei ʻana i ka metallurgical non-ferrous, ka mana wela, nā kapuahi arc submerged a me nā ʻoihana ʻē aʻe, me nā hiʻohiʻona o ka pale ʻana a me ke kūpaʻa wela kiʻekiʻe.

Nā ʻāpana refractory:me nā paipu pale thermocouple, nā puʻupuʻu riser, nā lima hoʻomehana, a me nā mea ʻē aʻe, i hoʻohana ʻia i nā kiln wela kiʻekiʻe a me nā lewa like ʻole, me ka conductivity thermal kiʻekiʻe a me ka pale ʻana i ka corrosion.

Nā kiʻi kikoʻī

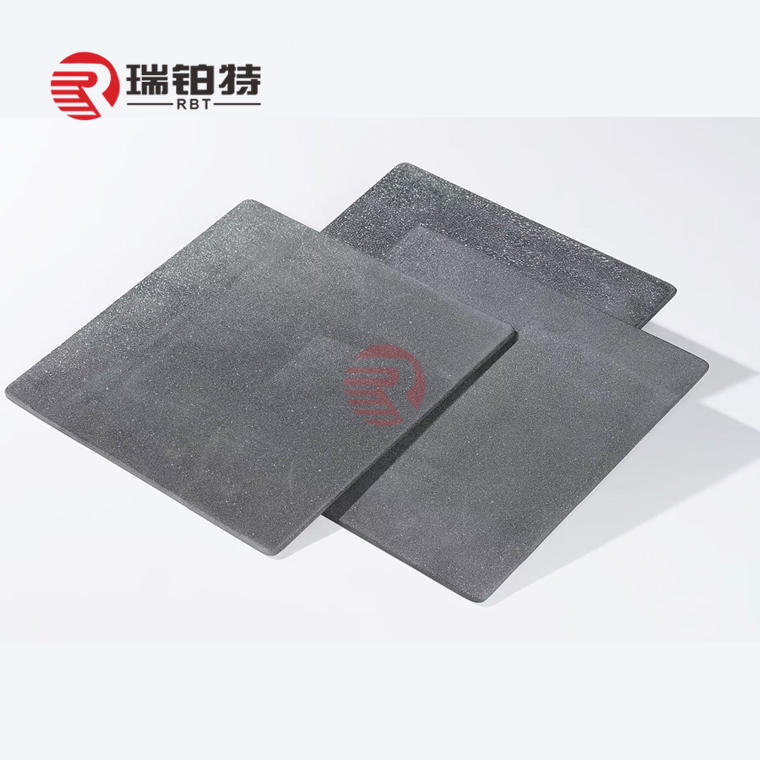

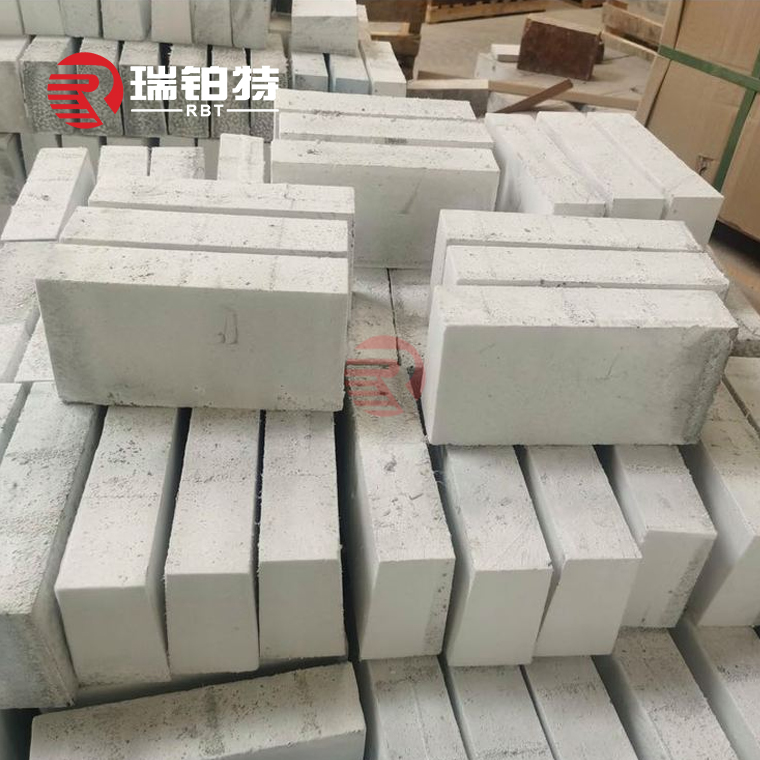

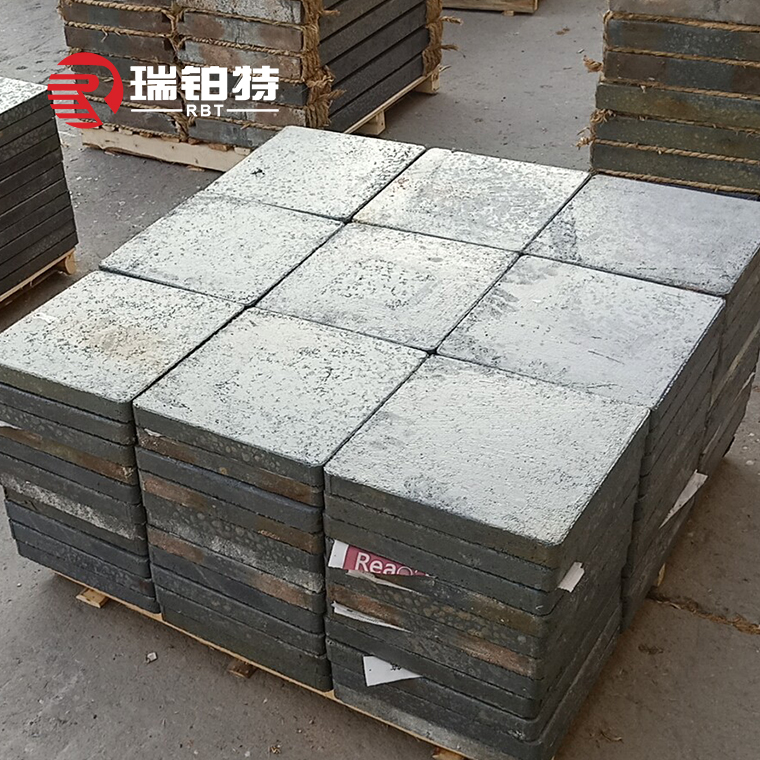

Pāpaʻa Silicon Carbide

Pāpaʻa Silicon Carbide

Pāpaʻa Silicon Carbide

Pāpaʻa Silicon Carbide

Pāpaʻa Silicon Carbide

ʻO nā paipu hoʻoheheʻe Silicon Carbide

Paipu Silicon Carbide

Pāpaʻa Silicon Carbide

ʻO nā ʻāpana Silicon Carbide

ʻO nā paipu pale silikoni

Pāpaʻa Kapili Silika

Pilikia karbida

5. ʻO nā huahana silicon carbide i hoʻopaʻa ʻia

Hana ʻia nā huahana silicon carbide i hoʻopaʻa ʻia ma ka hui ʻana i nā ʻāpana kalapona silicon me ka pauka oxide (e like me ka silicon dioxide a i ʻole mullite), kaomi a me ka sintering i ka wela kiʻekiʻe. ʻO kona hiʻohiʻona ʻo ia i ka wā o ka sintering a me ka hoʻohana ʻana, ua uhi ʻia ke kiʻi oxide ma luna o nā ʻāpana silicon carbide, kahi e hoʻomaikaʻi nui ai i ka pale oxidation a me ka ikaika wela kiʻekiʻe.

Loaʻa iā ia nā hiʻohiʻona o ka ikaika flexural kiʻekiʻe kiʻekiʻe, ke kūpaʻa haʻalulu maikaʻi, ka conductivity thermal kiʻekiʻe, ke kūpaʻa ʻana a me ke kūpaʻa ikaika i nā ʻano erosion lewa, a he mea mālama ola maikaʻi no nā umu ahi.

(2) Nā huahana nui:

ʻO nā huahana silicon carbide i hoʻopaʻa ʻia:Hoʻohana kēia huahana i ka silicon dioxide (SiO2) ma ke ʻano hoʻopaʻa. ʻO ka maʻamau ʻo 5% ~ 10% o ka pauka silicon dioxide a i ʻole ka pauka quartz i hui pū ʻia me nā ʻāpana silicon carbide (SiC). I kekahi manawa hoʻohui ʻia kahi flux. Ma hope o ke kaomi ʻana a me ka hana ʻana, puhi ʻia i loko o kahi kiln maʻamau. ʻO kona hiʻohiʻona ʻo ia i ka wā o ke kī ʻana a me ka hoʻohana ʻana, ua uhi ʻia ke kiʻi ʻoniʻoni silicon dioxide ma nā ʻāpana silicon carbide, kahi e hoʻomaikaʻi nui ai i ka pale oxidation a me ka ikaika wela kiʻekiʻe. Hoʻohana nui ʻia kēia huahana i nā papa kiln no ka puhi ʻana i ka porcelain (> 1300 ℃), a ʻoi aku kona ola lawelawe ma mua o

ua pālua ʻia i nā huahana silicon carbide i hoʻopaʻa ʻia. ?

ʻO nā huahana carbide silika i hoʻopaʻa ʻia ʻo Mullite:Hoʻohui kēia huahana i ka pauka α-Al2O3 a me ka pauka silicon dioxide i nā mea hana silicon carbide. Ma hope o ka paʻi ʻana a me ka hoʻokumu ʻana, ua hui pū ʻia ʻo Al2O3 a me SiO2 e hana i ka mullite i ka wā o ka sintering. I ka wā o ka hoʻohana ʻana, ʻo ka silicon dioxide i hoʻokumu ʻia e ka oxidation o ka silicon carbide i hana ʻia i ka mullite me Al2O3. Loaʻa i kēia mea ke kūpaʻa haʻalulu wela maikaʻi a hoʻohana nui ʻia i ka hana ʻana i nā saggers porcelain a me nā papa.

Nā kiʻi kikoʻī

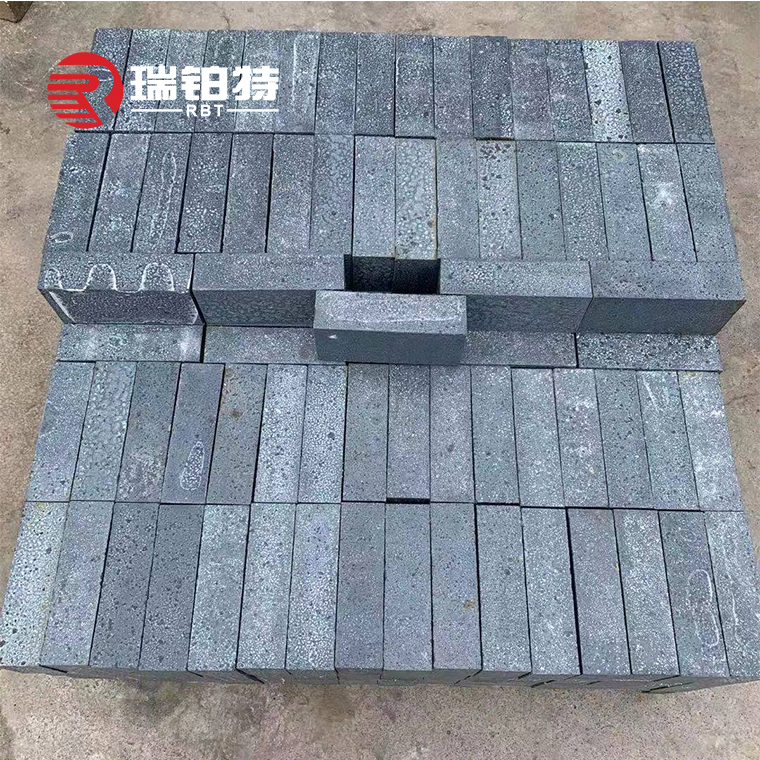

Pāpaʻa Kapili Silika

Pilikia karbida

Pāpaʻa Kapili Silika

SiC Microcrystalline Paipu

Papa SiC Microcrystalline

Papa SiC Microcrystalline

ʻIkepili Hui

Shandong Robert New Material Co., Ltd.Aia ma Zibo City, Shandong Province, Kina, kahi kumu hana hana refractory. He ʻoihana hou mākou e hoʻohui i ka noiʻi a me ka hoʻomohala ʻana, ka hana ʻana, ke kūʻai aku, ka hoʻolālā kiln a me ke kūkulu ʻana, ʻenehana, a me nā mea refractory hoʻokuʻu aku. Loaʻa iā mākou nā lako piha, nā ʻenehana holomua, ka ikaika ʻenehana ikaika, ka maikaʻi o ka huahana maikaʻi, a me ka inoa maikaʻi. Uhi kā mākou hale hana ma luna o 200 mau ʻeka a ʻo ka puka makahiki o nā mea refractory i hoʻohālikelike ʻia ma kahi o 30000 tons a me nā mea refractory unshaped he 12000 tons.

ʻO kā mākou huahana nui o nā mea refractory:nā mea pale alkaline; aluminika silika refractory mea; nā mea refractory ʻaʻole i hoʻohālikelike ʻia; insulation thermal refractory mea; nā mea refractory kūikawā; nā mea refractory hana no nā ʻōnaehana hoʻolei mau.

Nīnau pinepine

Pono kōkua? E ʻoluʻolu e kipa i kā mākou hui kākoʻo no nā pane i kāu mau nīnau!

He mea hana maoli mākou, ua loea kā mākou hale hana i ka hana ʻana i nā mea refractory no nā makahiki he 30. Hoʻohiki mākou e hāʻawi i ke kumukūʻai maikaʻi loa, ʻoi aku ka maikaʻi ma mua o ke kūʻai aku a ma hope o ke kūʻai aku.

No kēlā me kēia kaʻina hana, loaʻa iā RBT kahi ʻōnaehana QC piha no ka haku mele a me nā waiwai kino. A e hoʻāʻo mākou i nā waiwai, a e hoʻouna ʻia ka palapala hōʻoia me nā waiwai. Inā loaʻa iā ʻoe nā koi kūikawā, e hoʻāʻo mākou i ka maikaʻi loa e hoʻokipa iā lākou.

Ma muli o ka nui, ʻokoʻa kā mākou manawa lawe. Akā ke hoʻohiki nei mākou e hoʻouna koke aku me ka maikaʻi i hōʻoia ʻia.

ʻOiaʻiʻo, hāʻawi mākou i nā hōʻailona manuahi.

ʻAe, ʻoiaʻiʻo, ʻoluʻolu ʻoe e kipa i ka hui RBT a me kā mākou huahana.

ʻAʻohe palena, hiki iā mākou ke hāʻawi i ka manaʻo maikaʻi loa a me ka hopena e like me kou kūlana.

Ua hana mākou i nā mea refractory ma mua o 30 mau makahiki, loaʻa iā mākou ke kākoʻo ʻenehana ikaika a me ka ʻike waiwai, hiki iā mākou ke kōkua i nā mea kūʻai aku e hoʻolālā i nā kiln like ʻole a hāʻawi i ka lawelawe hoʻokahi.