Hoʻolauna

I nā ʻoihana wela kiʻekiʻe—mai ka hana kila a hiki i ka hana aniani—ʻo nā mea kūpaʻa ke kumu o nā hana palekana a me ka pono. Ma waena o kēia mau mea,nā pōhaku mullitekū i waho no ko lākou kūpaʻa wela kūikawā, ke kūpaʻa i ka pala, a me ka ikaika mechanical. He mea koʻikoʻi ka hoʻomaopopo ʻana i kā lākou hoʻokaʻawale ʻana a me nā noi no nā ʻoihana e ʻimi nei e hoʻonui i ke ola o nā lako a hoʻemi i nā kumukūʻai hana. Hoʻokaʻawale kēia ʻatikala i nā ʻano koʻikoʻi o nā pōhaku mullite a me kā lākou hoʻohana maoli, e kōkua ana iā ʻoe e hana i nā hoʻoholo naʻauao no kāu mau pono ʻoihana.

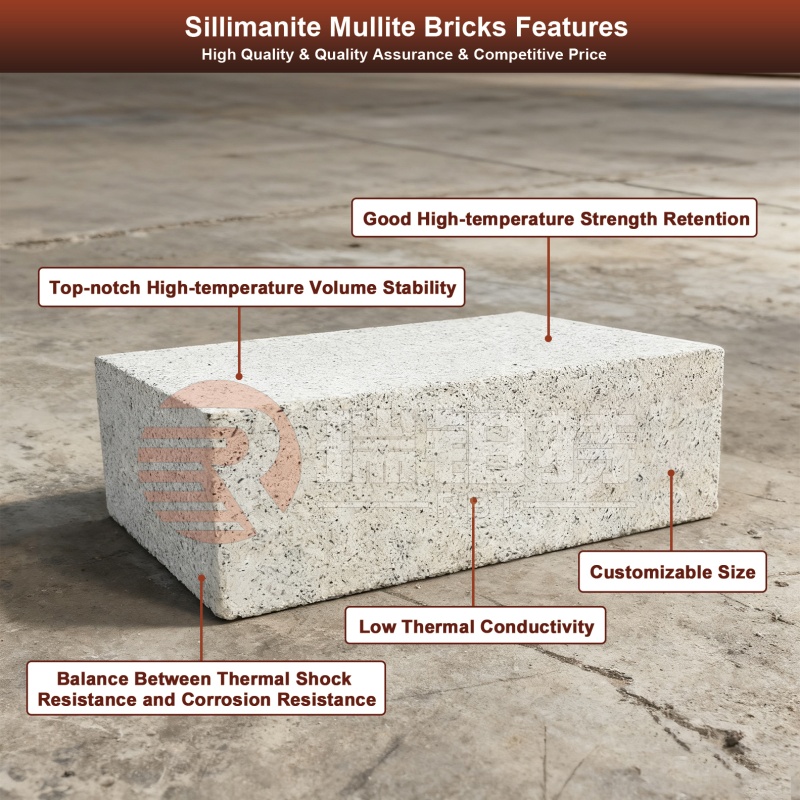

Ka Hoʻokaʻawale ʻana o nā Piliki Mullite

Ua hoʻokaʻawale ʻia nā piliki Mullite ma muli o nā kaʻina hana a me nā ʻāpana i hoʻohui ʻia, kēlā me kēia i hana ʻia no nā koi ʻoihana kikoʻī.

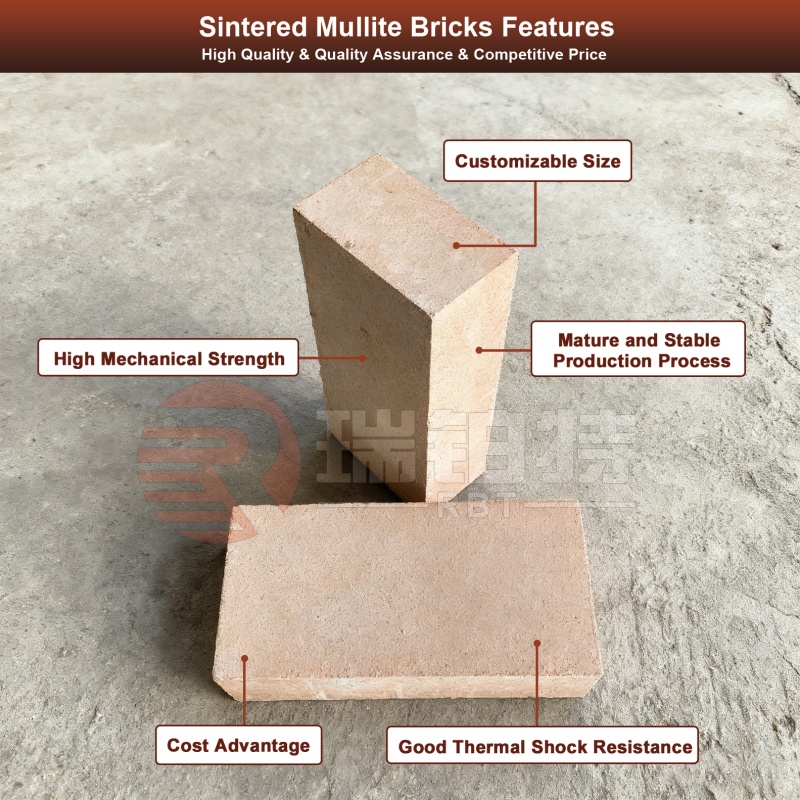

1. Nā Piliki Mullite Sintered

Hana ʻia ma ke kāwili ʻana i ka alumina maʻemaʻe kiʻekiʻe a me ka silica, ke hoʻopili ʻana i ka hui ʻana, a me ka sintering ʻana i nā mahana ma luna o 1600°C, ʻo nā piliki mullite sintered e haʻaheo i kahi ʻano paʻa a me ka porosity haʻahaʻa (ma lalo o 15%). Hāʻawi kēia mau ʻano iā lākou i ke kūpaʻa maikaʻi loa i ka ʻaʻahu a me ke kūpaʻa ʻana i ka haʻalulu wela—kūpono no nā wahi me nā loli pinepine o ka mahana. ʻO nā hoʻohana maʻamau e pili ana i nā uhi no nā umu keramika, nā kapuahi puhi wela o ka umu pahū, a me nā keʻena kuni paila.

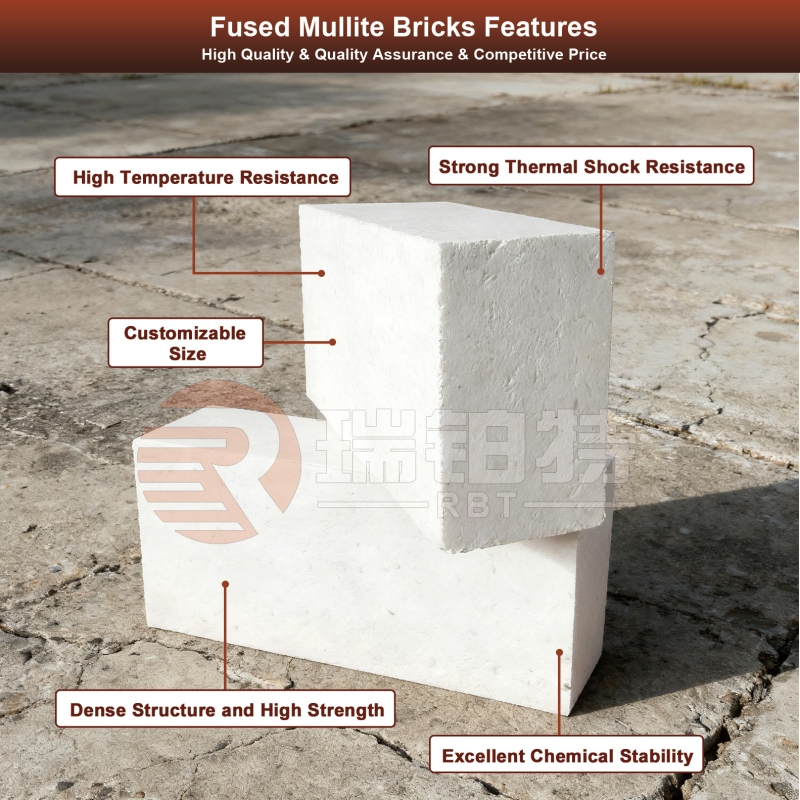

2. Nā Piliki Mullite i hoʻoheheʻe ʻia

Hana ʻia ma ka hoʻoheheʻe ʻana i nā mea maka (alumina, silica) i loko o kahi umu arc uila (ma luna o 2000°C) a me ka hoʻolei ʻana i ka hui hoʻoheheʻe ʻia i loko o nā ʻōmole, he haʻahaʻa loa nā pae haumia o nā piliki mullite i hoʻoheheʻe ʻia a me ka maʻemaʻe crystalline kiʻekiʻe. ʻO ko lākou kūpaʻa kiʻekiʻe i ka ʻino kemika (e laʻa, mai ke aniani hoʻoheheʻe ʻia a i ʻole nā slags) e hoʻolilo iā lākou i koho kiʻekiʻe no nā mea hoʻoulu hou o ka umu aniani, nā ʻauʻau tin aniani lana, a me nā lako ʻē aʻe i hōʻike ʻia i nā media hoʻoheheʻe ikaika.

3. Nā Piliki Mullite Māmā

Hana ʻia ma ka hoʻohui ʻana i nā mea hana pore (e laʻa, sawdust, graphite) i ka wā o ka hana ʻana, he 40-60% ka porosity o nā piliki mullite māmā a he haʻahaʻa loa ka density ma mua o nā ʻano sintered a fused-cast paha. ʻO ko lākou pono nui ka haʻahaʻa o ka thermal conductivity (0.4-1.2 W/(m·K)), kahi e hōʻemi ai i ka nalowale o ka wela. Hoʻohana nui ʻia lākou ma ke ʻano he mau papa insulation i loko o nā kilns, nā umu, a me nā lako hana wela, kahi e hoʻoikaika ai ke kaumaha a me ka pono o ka ikehu.

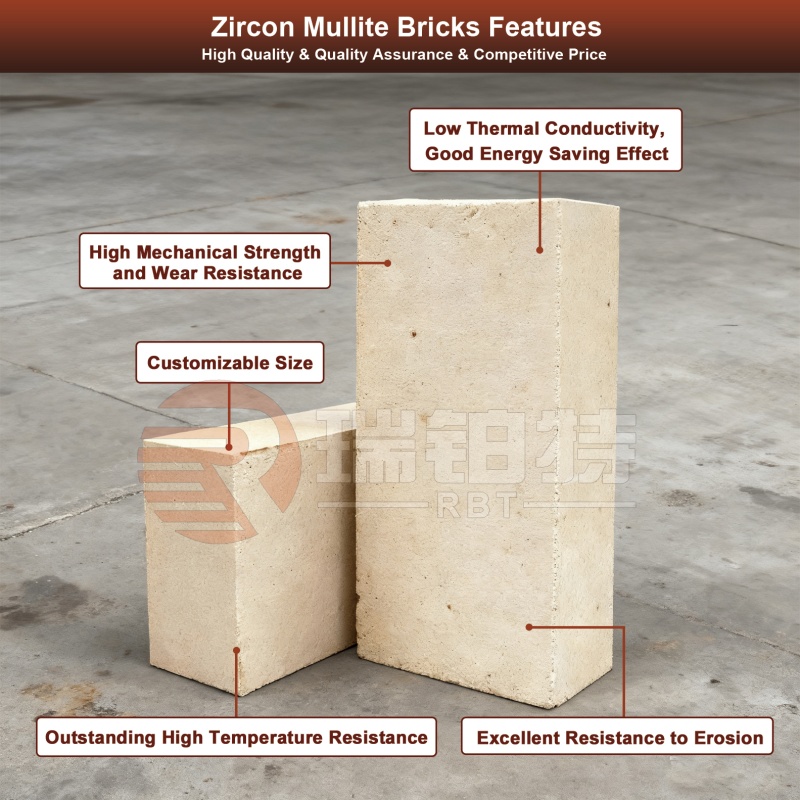

4. Nā Piliki Mullite Zircon

Ma ka hoʻohui ʻana i ka zircon (ZrSiO₄) i loko o ka hui ʻana o nā mea maka, loaʻa i nā piliki zircon mullite ka hana wela kiʻekiʻe i hoʻonui ʻia—hiki iā lākou ke kū i nā mahana a hiki i 1750°C a pale aku i ka ʻino ʻana mai nā ʻōpala waikawa. ʻO kēia ka mea e kūpono ai lākou no nā wahi ʻino e like me nā umu hoʻoheheʻe metala ʻole-ferrous (e laʻa, nā cell hoʻemi alumini) a me nā wahi puhi sima rotary kiln.

Nā Hoʻohana o nā Piliki Mullite

ʻO ka maʻalahi o nā piliki Mullite e lilo ia i mea nui loa ma nā ʻoihana wela kiʻekiʻe.

1. ʻOihana kila

ʻO ka hana kila e pili ana i nā mahana koʻikoʻi (a hiki i 1800°C) a me nā ʻōpala ʻino. Hoʻopili ʻia nā pōhaku mullite sintered i nā kapuahi wela, kahi e pale ai ko lākou kūpaʻa haʻalulu wela i ka haki ʻana mai ka hoʻomehana wikiwiki/hoʻomaʻalili ʻana. Mālama nā ʻano hoʻoheheʻe fused-cast i nā ladles a me nā tundishes, e hōʻemi ana i ka ʻino ʻana o ka slag a hoʻolōʻihi i ke ola o nā lako ma 20-30% i hoʻohālikelike ʻia me nā refractories kuʻuna.

2. ʻOihana Sima

Hana nā umu sima rotary ma 1450–1600°C, me nā ʻōpala alkaline e hoʻopilikia nui ana i ka ʻino. Hoʻopili nā piliki mullite Zircon i ka ʻāpana puhi o ka umu, e kūʻē ana i nā hoʻouka kaua alkali a mālama i ke kūpaʻa o ke kūkulu ʻana. Hana pū nā piliki mullite māmā ma ke ʻano he mau papa insulation, e hōʻemi ana i ka hoʻohana ʻana i ka ikehu ma 10–15%.

3. ʻOihana Aniani

He ʻino loa ke aniani hoʻoheheʻe ʻia (1500–1600°C), e hana ana i nā piliki mullite i hoʻoheheʻe ʻia i mea nui no nā mea hana hou o ka umu aniani a me nā uhi o ka pahu. Pale lākou i ka haumia o ke aniani a hoʻolōʻihi i ka manawa hana o ka umu i 5-8 mau makahiki, mai 3-5 mau makahiki me nā mea ʻē aʻe.

4. Nā ʻOihana ʻē aʻe

I ka hoʻoheheʻe ʻana i ka metala ʻaʻole ferrous (alumini, keleawe), kūʻē nā piliki zircon mullite i ka metala i hoʻoheheʻe ʻia a me ka ʻino ʻana o ka slag. I loko o nā petrochemicals, hoʻopili nā piliki mullite sintered i nā umu haki ma muli o ko lākou kūpaʻa wela. I loko o nā keramika, hoʻopaʻa nā piliki mullite māmā i nā umu, e hoʻemi ana i ka hoʻohana ʻana i ka ikehu.

Hopena

ʻO nā ʻano like ʻole o nā piliki Mullite—sintered, fused-cast, lightweight, a me zircon—e hoʻokō i nā pono kūikawā o nā ʻoihana wela kiʻekiʻe. Mai ka hoʻonui ʻana i ka pono o ka umu kila a hiki i ka hoʻolōʻihi ʻana i ke ola o ka umu aniani, hāʻawi lākou i nā pono hiki ke ʻike ʻia: ke ola lōʻihi o nā lako, nā kumukūʻai ikehu haʻahaʻa, a me ka hoʻemi ʻana i ka manawa hana. I ka wā e alualu ai nā ʻoihana i ka huahana kiʻekiʻe a me ke kūpaʻa, e mau ana nā piliki mullite i mea nui. E koho i ke ʻano kūpono no kāu noi, a wehe i ko lākou hiki piha.

Ka manawa hoʻouna: ʻOkakopa-31-2025